process and production of ncrete

2021-03-27T17:03:18+00:00

Concrete Production Process

The Concrete Production Process All concrete is made from a mixture of cement, aggregates and water However, different types of concrete can have different percentages of water in it, or different types of aggregates Concrete Production and placing Process includes following stages that are given below Batching of concrete Mixing of concrete Transportation of concrete Placing of concrete Compaction of concrete Curing of concrete 1 Batching of concrete:Concrete Production, Placement, Curing Process After concrete is placed at the desired location, the next step in the process of concrete production is its compaction Compaction consolidates fresh Concrete: Manufacturing Process BrainKart

Concrete Production an overview ScienceDirect Topics

Concrete production is a highly intensive energyconsuming process and presently facing a number of challenges in reducing the carbon footprint and making it more economic Sustainable technologies in maintaining concrete structures are proving to be a great challenge Microbially induced carbonate precipitation (MICP) has developed as a novel and sustainable technique Concrete Manufacturing Process consists of many stages The Concrete mix for delivery from a plant instead of mixing on the job site The concrete mixes, transports and delivers to a construction site to place in formworks for construction And to form various structures, like a column, beam, slab, etcConcrete Manufacturing Process in modern constructionProcess The manufacture of concrete is fairly simple First, the cement (usually Portland cement) is prepared Next, the other ingredients—aggregates (such as sand or gravel), admixtures (chemical additives), any necessary fibers, and water—are mixed together with the cement to form concrete At the cement production factory, the How concrete is made material, manufacture, making,

IELTS Task 1 Process Cement Concrete Production

IELTS Task 1 Process Cement and Concrete Production Below is a sample band 9 answer to a process task 1 question on concrete production Source: Cambridge English IELTS Past Papers Question – The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposesCement production involves more steps as compared to the production of concrete but the former requires less number of raw materials than the latter Concrete is the final output which is directly used for the building process, whereas cement is a semifinished product and needs further processing Body Paragraph 1IELTS Report on cement and concrete making process The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes ( 157 Words , 10 Sentences, 4 Paragraphs, Band 9) The first diagram illustrates the process of cement manufacture, and the second diagram shows the materials that go into the production of IELTS Writing Task 1 – Cement and concrete making process

Concrete Production, Placement, Curing Process

Concrete Production and placing Process includes following stages that are given below Batching of concrete Mixing of concrete Transportation of concrete Placing of concrete Compaction of concrete Curing of concrete 1 Batching of concrete:Concrete remains the No 1 building product in the world Its continued relevance owes a great deal to the precast concrete production process and the product stability and durability that this process creates A Brief Overview of the Precast Concrete Production Process Preparing the Forms First, we prepare the formsPrecast Concrete Production Process: The Basics Rogue Concrete Design Production Concrete is a mixture of two components: aggregates and paste The paste, comprised of cement and water, binds the aggregates (usually sand and gravel or crushed stone) into a rocklike mass as the paste hardens A properly proportioned concrete mix possesses acceptable workability of the freshly mixed concrete and Concrete Design Production Portland Cement

Process Production Graphic Concrete

PROCESS PRODUCTION Graphic Concrete allows you to impart nearly any pattern, image or design onto precast surfaces It opens up an unlimited range of design possibilities with the renowned resilience of precast concrete The technology transfers custom or stock graphics as a surface retarder via membrane placed at the bottom of the precast form Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process, the chemical bonds of the raw materials are broken down and then they are The Cement Manufacturing Process Advancing MiningCement production involves more steps as compared to the production of concrete but the former requires less number of raw materials than the latter Concrete is the final output which is directly used for the building process, whereas cement is a semifinished product and needs further processing Body Paragraph 1IELTS Report on cement and concrete making process

Cement Manufacturing Process: What is Cement

Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is 2 天前 ADVERTISEMENTS: The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of Cement Manufacturing Process: How the Cement is Made? The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes ( 157 Words , 10 Sentences, 4 Paragraphs, Band 9) The first IELTS Writing Task 1 – Cement and concrete

production process cement lemasderoquegrisefr

The manufacturing process Hoffmann Green Cements A clean and revolutionary cold manufacturing process Hoffmann Green has initiated a technological breakthrough based on changing the composition of cement so that it does not contain clinker, the main source of CO2 emissions in traditional cement production, as well as creating a cold and clean cement Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process, the chemical bonds of the raw materials are broken down and then they are The Cement Manufacturing Process Advancing MiningCement production involves more steps as compared to the production of concrete but the former requires less number of raw materials than the latter Concrete is the final output which is directly used for the building process, whereas cement is a semifinished product and needs further processing Body Paragraph 1IELTS Report on cement and concrete making process

Process and Equipment of the Cement Production Line

① dryprocess cement production process drying and grinding raw materials together, or first dried by grinding the raw material powder feeding dry kiln burning mature But people also the raw material powder ball made of raw material, adding an appropriate amount of water fed into the kiln burning mature Lepol method, called semidry, it is still a kind of dry Cement Production Process and Reactions Each step of cement manufacturing, physical conditions and reactions occurred are explained here Raw material transportation Limestone is carried to the plant from mining place usually by a train Some cement plants import clinker from other country or plant and add gypsum to produce cementCement Production and Manufacturing Process Portland The given two diagrams illustrate the needed equipment and the process of making cement and together with the production of concrete Cement is one of the ingredients in concrete Overall, there are five (write out small Writing Task 1 Process Cement And Concrete

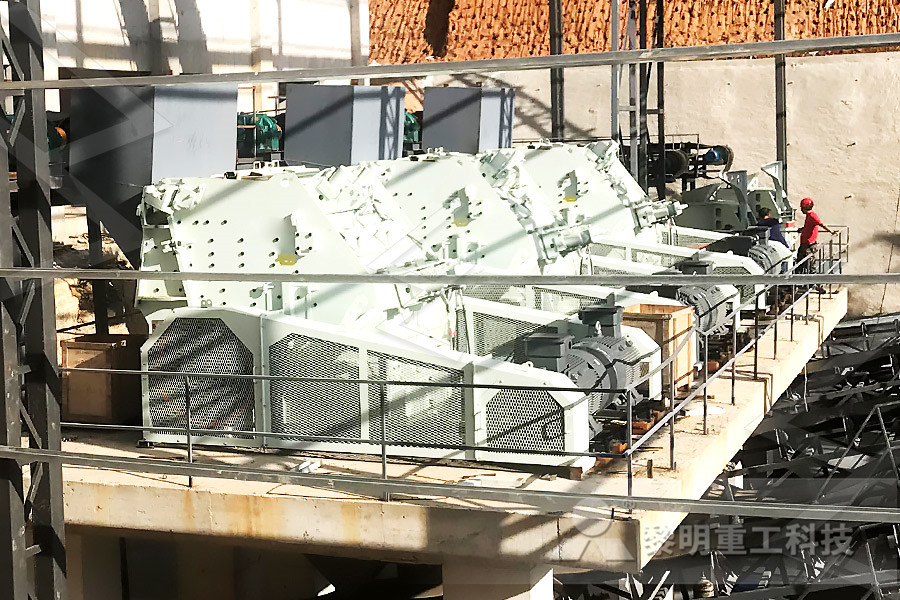

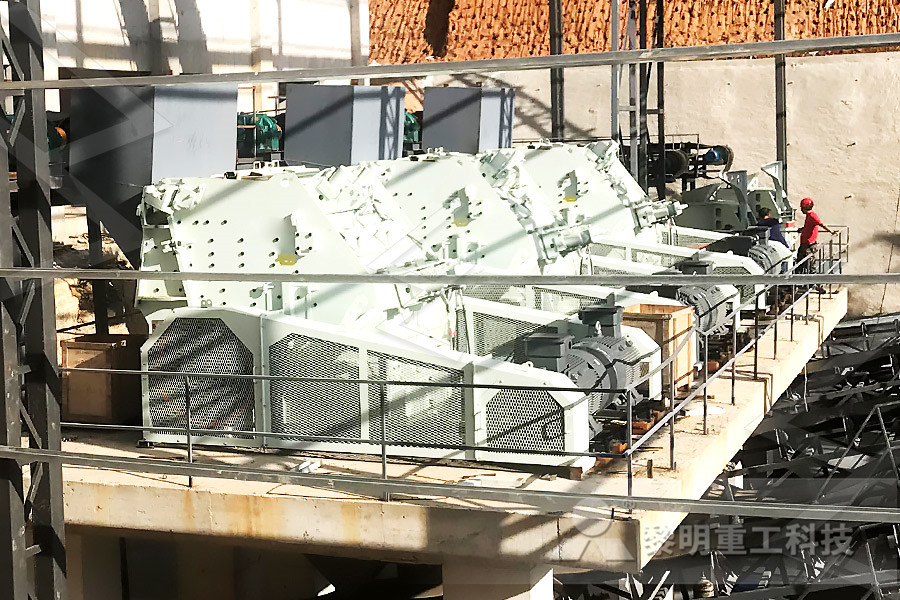

Concrete slab production Masa Group

The concrete slab production process is based on the compaction of concrete utilizing hydraulic pressing In this procedure, two concrete layers are filled into the Masa slab press successively and compacted in a mould The result is a twolayer slab The advantage of this method is that it gives concrete slab manufacturers great creative freedom Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is Cement Manufacturing Process: What is Cement The manufacturing process Hoffmann Green Cements A clean and revolutionary cold manufacturing process Hoffmann Green has initiated a technological breakthrough based on changing the composition of cement so that it does not contain clinker, the main source of CO2 emissions in traditional cement production, as well as creating a cold and clean cement production process cement lemasderoquegrisefr

Decarbonization options for cement production process: A

Download Citation Decarbonization options for cement production process: A technoeconomic and environmental evaluation The longterm environmental targets require significant cuts 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement Manufacturing