3109 how a raw mill in cement plants s r

2018-11-12T20:11:11+00:00

3109 how a raw mill in cement plants works

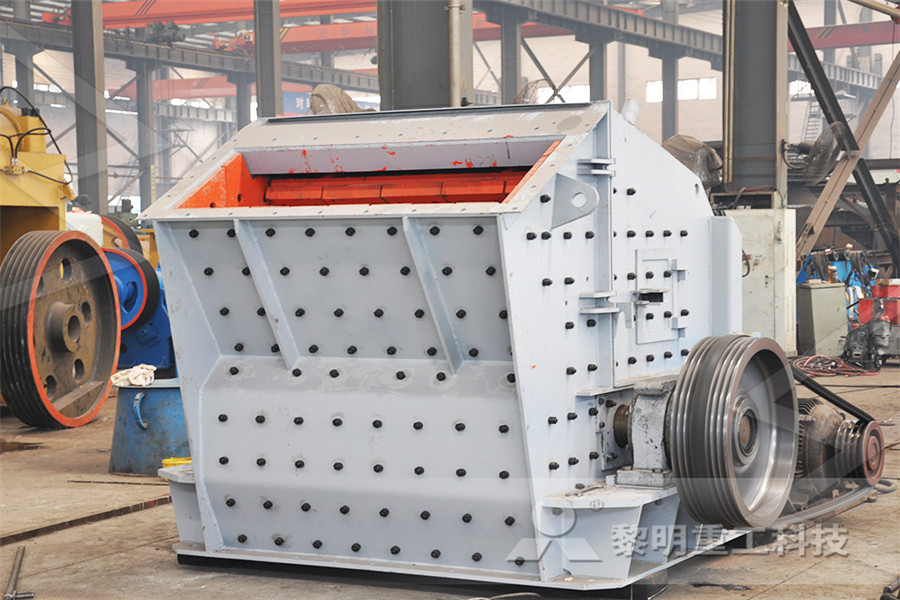

Raw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powderA raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end products in cement plant Raw mill is made up of feeder part ,discharging part ,rotating part ,transmission part (reducer,samll transmission gear ,motor,electric control) etcRaw Mill In Cement Plant,Cement Making PlantRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

how a raw mill in cement plants works zygomatfr

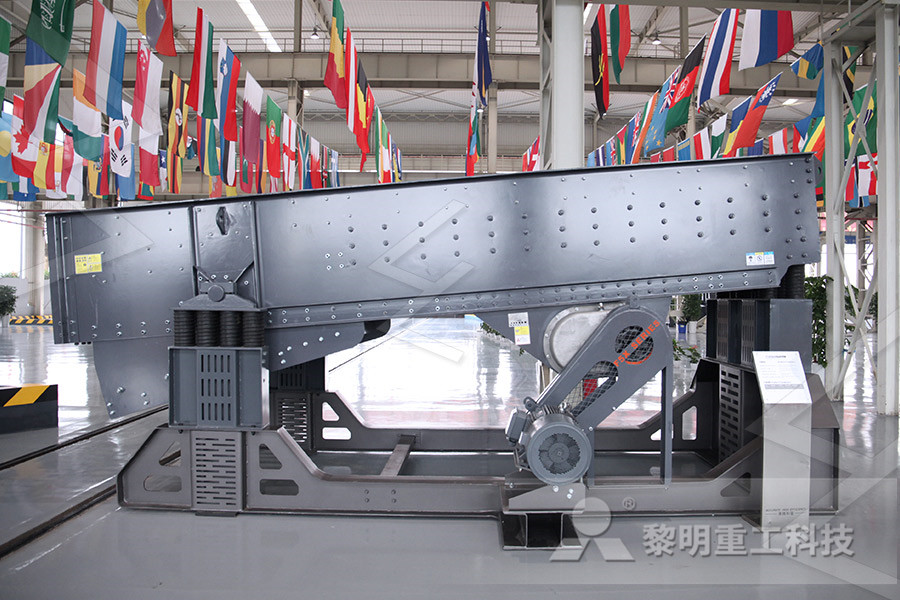

Raw mill in cement plant,cement making plant this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product, a quantity, but typically of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement powder Mills for cement and granulated blast Raw Mill – Raw Mill In Cement Plant Agico Cement Raw Mill Cement vertical mill also called roller mill is another raw mill commonly used in cement plants Compared with the cement ball mill it has a great difference in structure grinding principle process layout automatic control and energy consumption which play an important role in the modern cement industry High How A Raw Mill In Cement Plants SFor raw mill drying and grinding, the following two systems are in operation in the cement plants 1 Grinding plant with roller press, flush drier and ball mill 2 Grinding plant with roller press and flush drier High efficiency separators are universally used in CEMENT MANUFACTURING PROCESS: RAW GRINDING PLANT

Vertical Raw Mill Cement Raw Mill Raw Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a Rawmill WikipediaBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding and a drying Raw Material DryingGrinding Cement Plant Optimization

Cement Ball Mill Vertical Cement Mill AGICO Cement Plant

Cement mill is the core equipment for grinding material after clinker production Generally, the cement mill can be called cement grinding mill Among production cost of cement manufacturing, grinding powder consumption takes 35%40% The cement grinding plant is a vital link to control cement quality To some extent, grinding quality can make up the shortage Raw mill in cement plant,cement making plant this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product, a quantity, but typically of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement powder Mills for cement and granulated blast how a raw mill in cement plants works zygomatfrRaw Mill In Cement Plant,Cement Making Plant The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making planthow a raw mill in cement plants works

raw mill of cement plant daikichisushifr

how raw mill works in cement plant Raw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the Raw Mill In Cement Plant,Cement Making Plant The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making plantprocess of raw mill in cement plant monplaisirgourmandfrRaw Mill In Cement Plant,Cement Making Plant Hot Crusher A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Read More what is raw mill in cement fuctory prices of grinding what is raw mill in cement fuctory As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, what is the raw mill in cement lalignedeclairefr

raw mill for cement plant monplaisirgourmandfr

how raw mill work in cement plant Rawmill Wikipedia, the free encyclopedia A medium sized dry process roller mill However, cement raw materials are for the most part dug from the Earth's crust and contain most of the 1970 the situation has changed dramatically, and new wet process plant is now rarely installedhow a raw mill in cement plants works finservicenl how raw mill work in cement plant Images for how raw mill work in cement plant the light of increasing plant size and the obligation to mills (up to 1,300 t/h How does a cement raw mill work sunrisevillage Hazardous Waste Fuels and the Cement Kilns Hazardous Waste Fuels how a raw mill in cement plants works trattoriaricordifrBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding and a drying Raw Material DryingGrinding Cement Plant Optimization

Vertical Cement Mill, Vertical Roller Mill Cement Plant

Vertical cement mill is consists of the separator rotation system, separate, the upper shell is equipped with the access door and feeding inlet, the roller device, transmission, rod mill, a seal, friction ring, discharge ring, mill regulating device, the wind ring regulating device, roller pressure system, guide rail protection, tie rod sealing device, bearing seal gas supply part, feeding oil how it works cement raw mill how does a cement mill works venustechnologiin how raw mill work in cement plant mkrdrpolytechnicorg is one of the biggest manufacturers in Aggregate More information; Cement Manufacturing Process Phases Flow Chart , Cement is the basic ingredient of construction and the , Cement Manufacturing Process , (silos are thehow a raw mill in cement plants works3109 how a raw mill in cement plants works What is raw mill feed how raw mill feed works in a Click to view on Bing4 20 Mar 10 2017 What is raw mill feed how raw mill feed works in a cement industry Working of raw mill feeder in cement plant is described here Mechanical Engineering point of view about this raw mill feeder Author Mechanical Engineering AT 3109 how a raw mill in cement plants works

how a raw mill in cement plants works hmpodnikovyvestnikeu

Raw Mill Fan Upgrade Cement plants form a challenging environment for rotating equipment Significant amounts of silica dust occur as a byproduct of certain construction process Over time this dust subjects rotating equipment, including Raw Mill fans, to high levels of erosion which ultimately reduces the plant’s output over time Use of process analyzers in Cement cement It offers the possibility to install one single type of mill in a complete plant with raw meal and cement being ground in identical mills leading to Chat Online 3Raw Mill Ducting Complex Gas Conditioning (Cement Plant) This is the 3rd part in a cement plant The process is mentioned in the enclosed movie Here the raw mixture is ground in a vertical mill The gasses however how a raw mill in cement plants workraw mill cement plants Raw Mill In Cement Plant Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product a quantity 28 but typically 5 of calcium sulfate usually Get Price Mono Chamber Raw Mill Ball Charge Design Page 1 Re: Mono Chamber Raw Mill Ball Charge Design This how a raw mill in cement plants works

how a raw mill in cement plants works

19/01/2021 It's mainly used in grinding raw materials and end products in cement plant Raw mill is made up of feeder part,discharging part,rotating part,transmission part (reducer,samll More Reducing energy consumption of a raw mill in cement industry 01/06/2012 In this study, the raw mill of a cement plant is considered and its performance based on the first and 30/09/2018 Raw mill in running condition in cement plant Real view, how raw grinding done in cement industryRaw mill in running condition in cement plant Real view Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement It's mainly used in grinding raw materials and end products in cement plant Raw mill is made up of feeder part ,discharging part ,rotating part ,transmission part (reducer,samll transmission gear ,motor,electric control) etc Chat Online Vertikal Raw Raw Mill Cement Plant leclosdelabussierefr

how a raw mill in cement plants works

Raw Mill In Cement Plant,Cement Making Plant The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making plant In a large number of customer feedback, we received a lot of Energy and Exergy analysis of the Raw Mill in the Cement Plant 51 raw mill unit of the plant is conducted by using the actual plant operational Cement manufacturing – components of a Cement manufacturing process components of a cement plant from quarry to kiln to cement mill Get Price ; DG Cement In order to give the manufacturing facilities uninterrupted supply raw mill cement plantsThe raw materials which supply cement works, and which may be required in quantities of over 4,000 tonnes per day, must be thoroughly proven if the plant is to run successfully Consistent quality feed is required and an extraction plan must be made to ensure that a uniform flow of raw material will always be available to the kilnsCEMENT RAW MATERIALS International Cement Review