nickel ore process plant r

2019-10-01T22:10:14+00:00

Nickel Ore Processing Plants Nickel Ore Processing

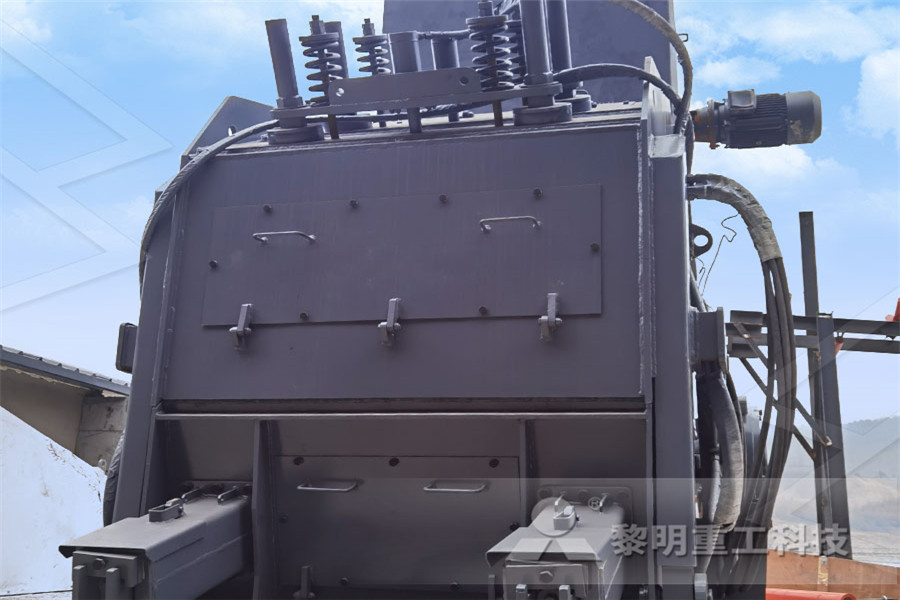

Nickel Ore Processing Plant Star Trace offers turnkey solutions for nickel ore processing plants We are one of the leading project suppliers for nickel ore plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the Nickel Ore Mining Process Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different Coppernickel sulfide ore beneficiation methods: The most important is the flotation The magnetic and the gravity separation is usually secondary dressing method Flotation copper sulfide nickel ore: Nickel Ore Mining Process Equipment Flow Cases JXSC20/03/2019 Nickel ore processing plant can directly use the excavator to shovel the ore The thinner ore layers are first collected by the bulldozer and then shovel nickel mining is divide into coppernickel mining and extraction of nickel from sulphide oreExtraction of Nickel Nickel Ore Mining Mining

Nickel Ore Mining Process,Processing Nickel

Nickel Ore Mining Process,Processing Nickel Ores,Nickel Process ServingBeijing HOT Mining Tech Co Ltd Nickel is convalescing by extractive metallurgy The majority sulfide ores have conservatively been processed utilize Nickel Ore Processing Plant Star Trace offers turnkey solutions for Nickel Ore processing plants We are one of the leading project suppliers for nickel ore processing plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution Nickel Ore Processing EquipmentNickel Ore Beneficiation Plant Nickel Ore ProcessingThere is a large plant of coppersulfide nickel ore in Ji Lin provice, China Xinhai providing perfect beneficiation process of threestage one close crushing, stage grinding, mixingseparating flotation, three stages dehydration of nickel concentrate and two stages dehydration of copper concentrate This process characterized by easier operation, longer flotation time, fewer nickel ore processing plant, nickel ore concentration

nickel processing Extraction and refining Britannica

In this process, the ore is mixed with special reagents and agitated by mechanical and pneumatic devices that produce air bubbles As these rise through the mixture, the sulfide particles adhere to their surfaces and are collected as a concentrate containing 6 to 12 percent nickel The waste material, or tailings, is frequently run through a second cleaning step before it is discarded The Taganito Project involved JGC constructing an HPAL smelting plant for processing lowgrade nickel ore into nickel metal The plant is located in the Taganito region on the island of Mindanao in the Philippines This plant includes two massive 1,000ton autoclaves (reactors) for leaching the lowgrade nickel oreNickel Smelting Plant Projects JGC HOLDINGS CORPORATIONAbout Euronickel Euronickel owns and operates a nickel ore processing plant in Kavadarci, North Macedonia The operation produces high quality ferronickel for use in the stainless steel producing industry Read More Process ProductsEuronickel Industries

THE DNi PROCESS™ Altilium Group

THE DNi PROCESS TM IS LEANER With significantly lower operating costs, and fast, efficient plant construction The DNi Process TM makes the extraction of ‘batterygrade’ nickel and cobalt more achievable, more affordable and more profitable In fact we’re promising to almost double the world’s nickel reserves whilst extracting all saleable metals from lateritic ore (Ni, Nickel is convalescing by extractive metallurgy The majority sulfide ores have conservatively been processed utilize hydrometallurgical techniques to fabricate a matter for more refining Latest go forward in hydrometallurgy have effect in Nickel Ore Mining Process,Processing Nickel 20/03/2019 Nickel ore processing plant can directly use the excavator to shovel the ore The thinner ore layers are first collected by the bulldozer and then shovel nickel mining is divide into coppernickel mining and extraction of nickel from sulphide ore Below the cover of the Ramu laterite nickel deposit in Papua New Guinea, there are yellow limonite deposits, residual Extraction of Nickel Nickel Ore Mining Mining

nickel ore processing plant nickel mining process

Star Trace offers turnkey solutions for nickel ore processing plants We are one of the leading project suppliers for nickel ore plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution More Nickel/Cobalt ore mining and processing operations, The proposed nickel/cobalt ore mining and processing A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrate The process has a vital advantage nickel ore processing plant, nickel ore concentration 09/12/2016 Now chatting: leawaysschool/solutionhtmlContact Us: leawaysschoolnickel ore processing plant and nickel Nickel ore processing plant YouTube

Nickel Ore an overview ScienceDirect Topics

The same is true for a minerals processing plant – it will have to treat 125% Ni ore twice as fast as 25% Ni ore to achieve the same annual production of nickelinconcentrate This will require about twice the amount of concentrator equipment and about double the investmentDirect Nickel Process Strictly Confidential DNi Process – Simplified Schematic 17 Mixed Hydroxide Product (MHP) produced with the DNi Process Ni(NO3) 2+ Mg(OH)2 = Ni (OH) 2 + Mg(NO3)2 Strictly Confidential Test Plant Layout 18 Strictly Confidential Test Plant Design • Plant was designed to treat 1 tonne per day of laterite ore • Successfully treated a range of Direct Nickel Process – Breakthrough Technologyscope ranging from equipment packages to turnkey plant delivery We have several processing alternatives for nickel and cobalt raw materials, ranging from pyrometallurgical to hydrometallurgical approaches Not only do our nickel and cobalt processing solutions help you achieve primary end products such as briquettes, cathodes, or batterygrade sulfates, but we Hydrometallurgical nickel and cobalt plants and processes

Vale Indonesia eyes 2026 completion for nickel HPAL plant

08/09/2021 We plan for mechanical completion in 2026,” said chief financial officer Bernardus Irmanto, referring to high pressure acid leach process of 08/12/2021 In 2014, the country even banned exports of nickel ore to force miners to process the ore domestically and thereby add value to its nickel production Chinese investments have already developed an integrated steel industry and Indonesia is now on track to repeat this success up the EV battery supply chain Indonesia’s first plant to process nickel for use in Indonesia’s Nickel Industrial Strategy Center for Nickel is convalescing by extractive metallurgy The majority sulfide ores have conservatively been processed utilize hydrometallurgical techniques to fabricate a matter for more refining Latest go forward in hydrometallurgy have effect in Nickel Ore Mining Process,Processing Nickel

nickel process plant nordcoffeetechfr

There are several steps involved in the process of extracting and processing nickel and cobalt from the ore, some of which are highly complex Our process plant consists of High Pressure Acid Leaching (HPAL) technology and a Refinery a reverse osmosis water treatment plant Learn More The World's Largest Nickelcobalt Wet Process Plant Is The CEO said that Processing Plant For Nickel Ore The plant has operated under a number of different owners since then with its growth linked to the global nickel and energy prices In the plant went through a restructuring process During 2018 GSOL invested in the successful restart of nickel ore processing at the plant under a processing contract and presented a Processing Plant For Nickel Ore09/12/2016 Now chatting: leawaysschool/solutionhtmlContact Us: leawaysschoolnickel ore processing plant and nickel Nickel ore processing plant YouTube

nickel ore processing plant, nickel ore concentration

A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrate The process has a vital advantagereceive copper concentrate with low grade nickel directly [ Cases ] There is a large plant of coppersulfide nickel ore in Ji Lin provice, 15/09/2020 Nickel beneficiation process 091520; 865 Views; icon 1; Nickel beneficiation process Nickel ore is mainly divided into coppernickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are completely differentNickel beneficiation process,process design for Euronickel owns and operates a nickel ore processing plant in Kavadarci, North Macedonia The operation produces high quality ferronickel for use in the stainless steel producing industry Read More Process Products Euronickel produces high quality, low carbon ferronickel granules comprising approximately 20% nickel and 80% iron that are primarily used in the Euronickel Industries

Unlocking millions of tonnes of nickel CSIRO

[Image changes to a pile of manufactured nickel rods and then to a rock of nickel sulphide ore] However, the majority of the world's reserves, around 70%, are laterites [Image changes to a factory scene with two men operating some machinery] Current sulphide deposits are depleting, and the industry is looking for more environmentally friendly and cost effective ways to Ore processing The Ravensthorpe ore body is distinctive in that it has a high silica content, which enables the limonite ore to be upgraded to almost twice the mined grade through a beneficiation plant – a simple scrubbing and screening BHP Ravensthorpe Nickel Operation, Australia In this study, hydrometallurgy method is applied to process nickel laterite of Morowali An important step in this process line is ore leaching This research is conducted to find a condition in (PDF) Nickel laterite processing technologies –