iron ore vertical grinding mill operation

2023-06-28T15:06:17+00:00

Research of iron ore grinding in a verticalrollermill

Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Within these test works, mill parameters like grinding pressure, separator speed and dam The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill ( Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemResearch of iron ore grinding in a verticalrollermill Abstract The application of vertical mills in regrind circuits is consolidated This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to ball mills, which are usually used at this stage In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit Vertical mill simulation applied to iron ores ScienceDirect

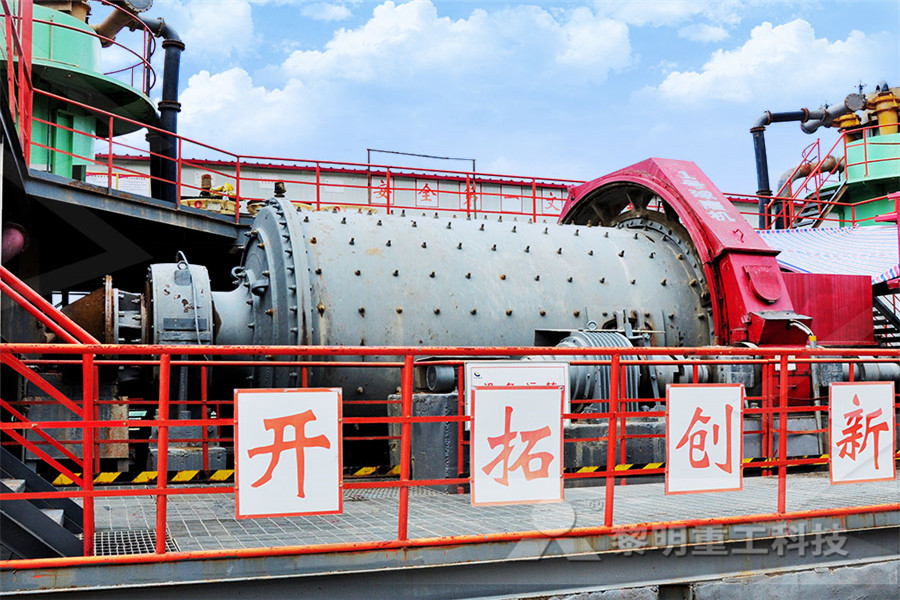

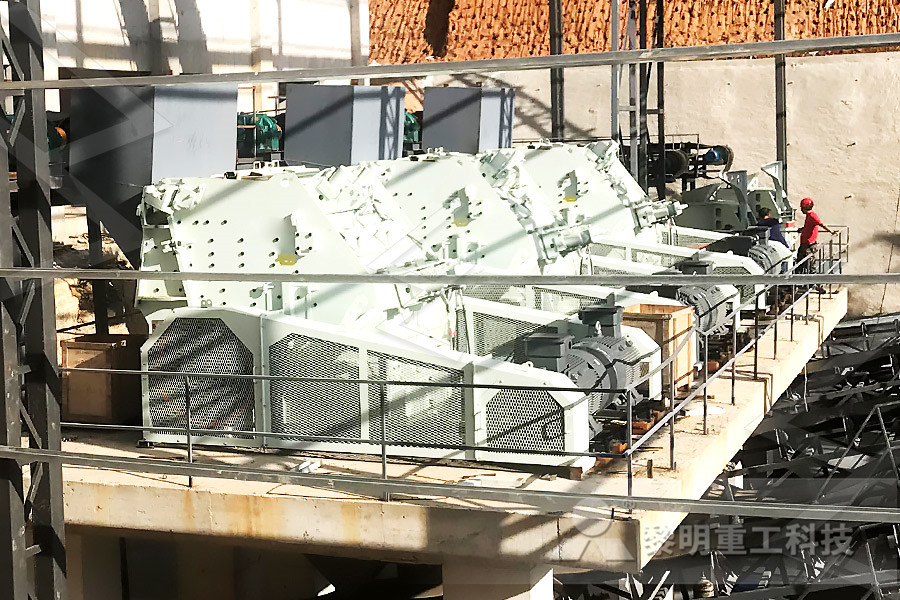

Iron ore grinding mill Grinding plants for Iron Ore

Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifying Ground material will be classified, coarse powder will fall back to the main mill for ground again The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile has been developed From March 1 to 4, 2020, meet our team from Loesche South Africa, America Germany at The World’s Premier Mineral Ores LoescheIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine

Vertimill vertical grinding technology reduces energy

"MinasRio uses 179 MW of power in its regrinding process while the application with ball mills would be 256 MW; this represents a significant reduction of 77 MW", says Rodrigo Vilela, Director of Operation of Anglo American's MinasRio system, part of Anglo American's Iron Ore Business Unit in BrazilVertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding raw coal, clinker, cement and/or slag, we Vertical roller mills offer supreme grinding between the density of gangue minerals (quartz) and iron ore ones (hematite and goethite) The vertical mill chosen was a VTM1500 (1500 cv) and it is fed with the concentrates of both fines and mechanical flotation circuits A new slurry distribution system was provided to the circuit objectingComparing ball and vertical mills performance: An

The Features of Cement Vertical Mill hcmilling

Grinding equipment: ball mill, vertical mill, tube mill, etc Production process: mixing limestone, clay and iron ore according to a certain ratio, after crushing, grinding and stirring, qualified raw meal powder will be produced Wet method iron ore vertical grinding mill operation Iron ore grinding mill amp; Grinding plants for Iron Ore Iron ore is an important industrial source is an iron oxide ore a mineral aggregate containing iron elements or iron compounds that can be economically utilized and there are many types of iron ore Application of Ultrafine Vertical MillIron Ore Vertical Grinding Mill Operationmill grinding Download Citation Iron ore vertical grinding mill operation mill grinding wikipedia overviewgrinding lawsgrinding machinesa mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting such comminution is an important unit operation in manyiron ore vertical grinding mill operation

iron ore vertical grinding mill operation

Vertical Mill,Vertical Roller Mill,Vertical Grinding Mill Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron Iron ore vertical grinding machine grinding power Iron Ore Vertical Grinding Mill Operation 2the ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etcs well as for ore dressing of both ferrous and Vertical Roller Mills For Iron Ore Grinding 「iron ore vertical grinding mill operation」iron ore 3 rollers vertical grinding mill iron ore 3 rollers vertical grinding mill, s iron ore vertical roller mill is a completely new and, Vertical Roller iron ore vertical grinding mill operation

iron ore vertical grinding mill operation

Vertical grinding mill or Raymond grinding mill grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder and then to installation, not only successfully complished delivery, but also the operation of the equipment at the scene was impressive, stable running Iron Ore Vertical Grinding Mill Pdf iron ore vertical grinding mill pdf praktijkmargrietnl Research of iron ore grinding in a verticalrollermill In case of the Kiruna ore there was the possibility to take samples of the concentration plant KA1 in Kiruna while the same feed material was ground as used for the tests with the vertical Vertical Mills For Iron Ore Grinding Mill China Tag Archives: vertical grinding mills Outotec to deliver ‘multiple’ Vertimills to Ferrexpo’s Ukraine iron ore ops 22nd June 2021 Comminution of minerals , Mine operation news , Mineral processing , Mining equipment , Steel and iron ore Ferrexpo , Iron ore , Outotec , Planet Positive , vertical grinding mills , Vertimill , VTM vertical grinding mills Archives International Mining

Fine Dry Grinding of Iron Ore for 911

Table of ContentsDesign Considerations for Selecting a Grinding SystemOpen vs Closed Circuit Dry GrindingEffect on Pellet QualityOperating Considerations Screening during the production of highgrade lump ore for Operation The HIGmill™ high intensity grinding mill comprises a mill body, shaft with grinding discs, shell mounted counter rings, gearbox, and drive The grinding chamber is filled up to 70% with grinding beads Rotating discs stir the charge HIGmill high intensity grinding mill Recently, the first TRM282 vertical mill applied to grind iron ore, developed and designed by Sinoma Equipment Group, was smoothly put into production and achieved the target in Hubei Fengshan Mineral Company 06MTPA Iron Ore Project The successful operation of the vertical mill made a beneficial quest for the application of material bed The First Vertical Mill Grinding Iron Ore Developed by

Vertical Roller Mill Great Wall

Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, Because the ore to be ground passes through the grinding machine only once, the product size is relatively coarse This type of process is commonly used in the first stage of the singlestage rod milling process or the first stage of the twostage grinding process with rod mills The ore can be ground from 2025 mm to about 3 mm at a timeIron ore grinding process,process design for grinding Vertical Roller Mill Capacity:20300 T/H Feeding size:100 mm Output Size:301000 Mesh Brief Introduction: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, espeVertical roller mill,Vertical Grinding mill,Vertical

Vertical roller mill operation processZhengzhou

At this time, vertical roller mill grinding work will begin The operation sequence of vertical roller mill is simple as follows: startup: hoist crusher,analyzer fan, main engine feeder When the vertical roller Mill stops, the machines should be shut down in the following order: 1 Close the feeder first and stop feeding; 2 Consequently, efficiency in energy used can be as much as 40% – 45% less than a wet ball mill circuit – noticed with all power going into the comminution of the ore Smarter process control ensures consistent grinding Vertical roller mills: The new leader in grinding Table of ContentsDesign Considerations for Selecting a Grinding SystemOpen vs Closed Circuit Dry GrindingEffect on Pellet QualityOperating Considerations Screening during the production of highgrade lump ore for Fine Dry Grinding of Iron Ore for 911

Comparing ball and vertical mills performance: An

between the density of gangue minerals (quartz) and iron ore ones (hematite and goethite) The vertical mill chosen was a VTM1500 (1500 cv) and it is fed with the concentrates of both fines and mechanical flotation circuits A new slurry distribution system was provided to the circuit objectingLow investment: the vertical raw mill set crushing, drying, grinding, grading transportation in one, simple system, compact layout, less space, it also can be arranged in the open air, save a lot of investment costs Low operation cost: small energy consumption and less damage reduce the running cost Environment protection and clean: small vibration, low noise, and good sealing, Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant