Cement grinding limestone r

2021-05-16T00:05:46+00:00

CEMENT Gebr Pfeiffer

For limestone grinding, the MPS mill is a proven and wellknown machine, which is installed in numerous plants With the development and introduction of the MVR mill, which was first used in the cement sector, another vertical roller mill is now available, also for limestone grinding This mill type covers a wide range of throughput rates15/09/2020 The percentage of limestone used has a significant impact on the cement grinding process and ultimately on the final cement performance characteristics It affects the grinding efficiency of the clinker, mill retention, mill internals coating, moisture input, grinding temperature, and cement flowabilityBlended Cements with Limestone GCP Applied Technologies20/12/2013 According to CEN, the use of CEM II limestone cements increased from 15 % in 1999 to 314 % in 2004 and became the single largest type of cement produced in Europe [ 5 ] In the conventional process of cement production, 30–80 kWh/t specific energy is consumed in cement grinding which equals 30 % of the total energy consumptionInfluence of grinding method and particle size

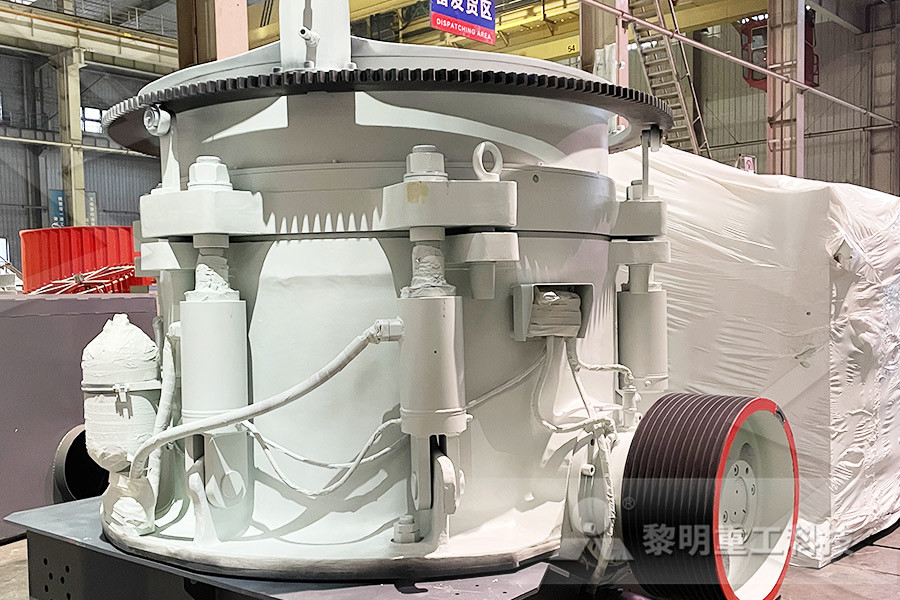

Huaxin Cement commissions grinding system at Maweni

01/12/2021 Huaxin Cement commissions grinding system at Maweni Limestone plant in Tanzania Written by Global Cement staff 01 December 2021 Print Tanzania: Huaxin Cement has commissioned the grinding system at its Maweni Limestone plant near Tanga The Chinabased company acquired the company from Athi River Mining (ARM) Cement in mid202020/07/2020 Step 4:Cement grinding and storage Clinker and gypsum for Ordinary Portland Cement(OPC) limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambers The two chambers have a certain Cement manufacturing process: Stepbystep guide CCE l 26/03/2015 Because the limestone is softer than the clinker it will grind preferentially, resulting in a cement with a better particle size distribution with less energy The limestone also requires less processing and does not undergo calcination, so it releases less waste in its productionUnderstanding Limestone in Cement Concrete Construction

Cement Grinding Mineral Processing Metallurgy

22/10/2016 A typical raw mix consists of 7585% limestone, 1225% shale, the balance consisting of silica or quartzite and iron oxide Exact proportioning is dependent upon their chemical properties before and after calcining to cement clinker For good kiln practice the grind required is 8892% – 200 mesh for standard cement, 99%200 mesh for high earlyCement grinding The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm)cement manufacturing Cementindusneed07/07/2020 The Chinese cement producer will pour US$116m into Maweni Limestone to settle its liabilities and add another US$30m to complete plant construction and an upgrade, according to Reuters Kenyanbased ARM Cement operates an integrated plant at Tanga and a grinding plant at Dar es SalaamMaweni Limestone Cement industry news from Global Cement

Cement grinding optimisation ScienceDirect

01/11/2004 grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 Advances in cement grinding technology is slow and these advances are limited to more developed countries Approximately 95% of the feed to the cement grinding circuit are clinker and the rest of the feed are “additives” which includes grinding limestone increased m ostly 3 to 5 microns particles, with no major effect on the particle sizes in the range of 5 to 3 0 microns R esults of this study have been confirmed by a (PDF) Effects of Intergrinding 12% Limestone with Feb 23, 2021 Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone, clay, sand, and iron ore in a rotary kiln The kiln is a large furnace that is fueled by coal, oil, gas, coke and/or various waste materialscement limestone grinding zygomatfr

Understanding Limestone in Cement Concrete Construction

26/03/2015 The biggest difference in production is that the limestone is added to the clinker blend before grinding Because the limestone is softer than the clinker it will grind preferentially, resulting in a cement with a better particle size distribution with less energy The limestone also requires less processing and does not undergo calcination, so it releases less waste in its 22/10/2016 Cement grinding using Grate Discharge principles developed in the ore milling industry applied to the cement industry Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay A typical raw mix consists of 7585% limestone, 1225% shale, the balance consisting of silica or quartzite and Cement Grinding Mineral Processing MetallurgyThis paper examines the behavior of Portland limestone cements (PLCs) made by intergrinding clinker, gypsum and limestone in a full sizecement plant, while varying the content of Influence of grinding method and particle size

The effects of grinding on the properties of Portland

01/11/2013 The limestone fillers content in cement has no real influence except at 7 days where the dry shrinkage is more substantial when the fillers content and/or the finer grinding are high The acceleration in hydration (see previously), which induces autogenous shrinkage at early age, is probably the cause of this increase This trend is less pronounced over longer time 01/11/2013 The interground OPC/limestone mixture shows accelerated initial hydration at water to powder ratios (w/p, where powder = cement + limestone) of 050 and 035 when compared with the samples before grinding At the lower w/p of 035, the OPC/limestone mixture appears much more efficient In the OPC/fly ash mixture, jet mill grinding also Jet mill grinding of portland cement, limestone, and fly Portlandlimestonecement Grinding Strength Porosity Stability Sorptivity abstract This paper presents a study of seven Tunisian cements with varying limestone filler content, manufactured on The effects of grinding on the properties of Portland

PROCESS ANALYSIS AND ENERGY EFFICIENCY IMPROVEMENT ON

PORTLAND LIMESTONE CEMENT GRINDING CIRCUIT by Sixto Humberto Aguero BS (M echanical Engineering), Universidad Nacional Autonoma de Honduras, 1992 MASc (Ene rgy Management), New York Institute of Technology, 2008 A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTER OF APPLIED 08/12/2014 Limestone moisture: 1% ; Cement outlet temperature: average 100 deg cel ; open circuit mill was used producing 20 tph ; no grinding aid used ; Responses will help me greatly going forward Thanks Shastri Reply Know the answer to this question? Join the community and register for a free guest account to post a reply 198 posts Time Posted 16/08/2014 Clinker grinding with limestone Page 1 of 1 CemNetgrinding limestone increased m ostly 3 to 5 microns particles, with no major effect on the particle sizes in the range of 5 to 3 0 microns R esults of this study have been confirmed by a (PDF) Effects of Intergrinding 12% Limestone with

cement grinding limestone

Grinding limestone cement Grinding hard clinkers Grinding hot clinkers Allow higher power reduction Higher Performance Grinding Aids Cement early strength can be increased by up to 20% Allow higher addition of fillers such as Pozzolana, PFA Slag Cement late stregth can be increased by up to 15% Allow higher addition of fillers such as limestone up to 25% Low 20/07/2020 Step 4:Cement grinding and storage Clinker and gypsum for Ordinary Portland Cement(OPC) limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambers The two chambers have a certain Cement manufacturing process: Stepbystep guide CCE l The purpose of the study is to promote Portlandlimestone cement in countries where these cements are not usually used Materials characterization showed that the grinding quality of (PDF) The Effects of grinding on the properties of

Use Limestone for Cement Grinding Page 1 of 1

Use Limestone for Cement Grinding Dear All, Our plant is using High grade limestone as filler for cement grinding We are going to change the limestone source, but this material is contaminated a bit clay and dolomite Anyone can share me the limit of clay can be contaminated in limestone without effect on cement quality? and how can we measure the % of clay in FTM limestone grinding mill is the star product of Henan Fote Heavy Machinery Co,ltdand it is a grinding mill is specialized in limestone grindingWith genuine components provided by world famous manufacturers and advanced technologies, FTM limestone grinding mill is your best choice to supply limestone powder for portland cement production,highgrade paper making cement industry limestone grinding mills to supply 200Jet Mill Grinding Of Portland Cement Limestone And Fly The first system is a blend of OPC and 15 limestone and the second system is a blend of OPC and 40 fly ash It was observed that when jet mill grinding is used the average particle size of the powders is decreased to approximately 4 μm or less with a narrower particle size distribution than that achieved using Limestone Particle Size In Cement Mill

Portland Limestone Cement CEMEX UK

Incorporating finely ground limestone, CEMEX Cemstone® contains lower levels of Portland cement clinker than CEM I alternatives meaning a lower level of carbon intensity but with equivalent levels of technical performance A small quantity of gypsum is introduced during grinding to control the setting characteristics of the cementCement Crushing and Grinding Plant We offer a series of equipment to form an automated production line for cement plants and offer a series of project services, including process design, civil construction, complete sets of equipment, installation and commissioning, and technical assistance Using the clinker production line, limestone raw Cement Crushing and Grinding Plant SBCCOCEMENTCement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement Cement clinker Wikipedia