grinding equipment pavement r

2019-06-13T21:06:23+00:00

Asphalt Pavement Grinding Equipment

Asphalt Pavement Grinding Equipment Recycled Asphalt Pavement Like Traditional Milling Micromilling Produces Material Which Can Be Recycled Into New Asphalt Pavements However RAP Produced By Micromilling Is Generally Smaller In Size And More Uniform This Means That The RAP From These Projects Will Require Less Crushing Than Usual Reducing The Costs Use power driven, selfpropelled grinding equipment with these characteristics: Diamond blades designed to smooth and texture Portland Cement concrete pavement Effective wheel base of at least 12 ft (36 m) Pivoting tandem bogey wheels at the front of the machine Rear wheels arranged to travel in the track of the freshly cut pavement Grinding head with the center no ncrete pavement grinding equipment fbmmenuiseriefrGrinding Scarifying Equipment Graco’s grinders and scarifiers are the choice of contractors looking to remove pavement markings, perform inlay grooving, and smooth uneven surfaces Our pavement marking removal equipment delivers unmatched results while being able to handle the daily demands of professional contractorsGrinding Scarifying Equipment Graco

Équipement de broyage et de scarifiage

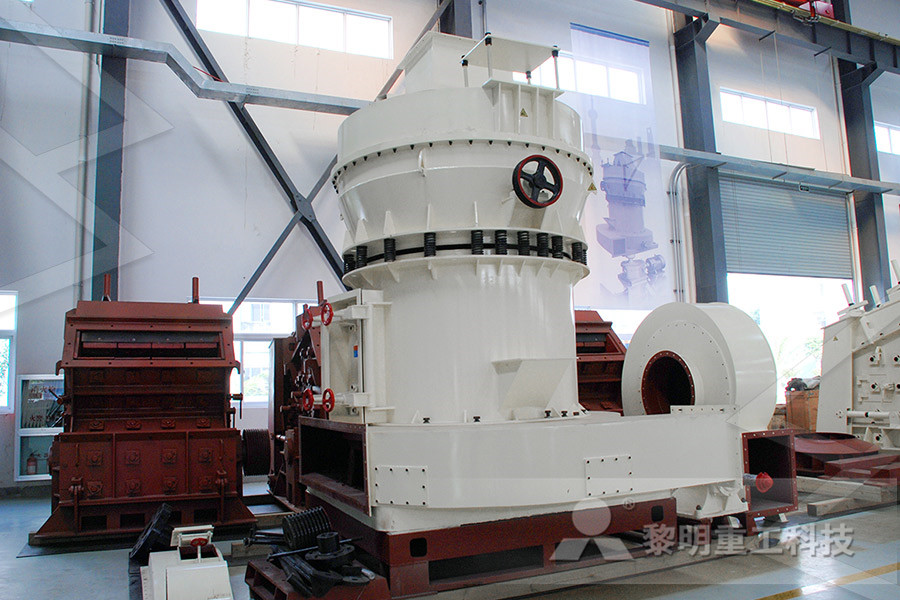

Les broyeurs et scarificateurs de Graco sont le choix préféré des entrepreneurs qui ont besoin d'enlever les marques de la chaussée, d'effectuer des rainures d'incrustation et de lisser les surfaces inégales Notre matériel d'enlèvement du marquage des chaussées donne des résultats inégalés et est conçu pour répondre aux exigences quotidiennes des entrepreneurs These concrete pavements include plain concrete pavement (PCP), discrete reinforced slabs within PCP (PCPR), jointed reinforced concrete pavement (JRCP), continuously reinforced concrete pavement (CRCP), and steel fibre reinforced concrete pavement (SFCP) A typical grinding machine used in Australia is shown inFigure 1 Technical Guide Grinding Concrete PavementsAt the cost of employing diamond grinding equipment, several benefits are observed The process is used to restore or improve pavement ride quality Restoring ride through grinding improves traffic carrying capacity and adds value to an inplace pavement Diamond grinding provides numerous benefits over other rehabilitation alternativesDiamond grinding of pavement Wikipedia

Diamond Grinding Asphalt Pavement for Improved Performance

Composite Pavement Weight of Grinding Machine Deflects Joint and Pushes Down Any Faulting at the Joint Costs Typically done on an hourly basis Ranges $70000 ‐$100000 per hour Additional mobilization costs are standard $250 – $350 per mile per unit Not uncommon to eliminate $50,000 ‐ $100,000 in penaltyPC1504 Pavement Grinder Groover; PC1504 Pavement Grinder Groover Diesel Powered Call the Nampa, ID facility at 18002250142 for more information More Views Product Description; FEATURES: • Capable of grinding to within 10” (254cm) of a vertical wall • Fast, nimble and easy to use • Equipped with odometer that measures total footage (meters) PC1504 Pavement Grinder Groover Diamond ProductsRMM collection ranges from extremely lightweight or small yet powerful milling machines that can be used for pavement operations to the large cold planer for maximum milling performance So whether you are milling asphalt, concrete highways or road,soil stabilizer,cold planer, asphalt,concrete

Pavement Grinding Equipment

431302 Equipment A Grinding Equipment Use power driven, selfpropelled grinding equipment with these characteristics: Diamond blades designed to smooth and texture Portland Cement concrete pavement Effective wheel base of at least 12 ft (36 m) Pivoting tandem bogey wheels at the front of the machine Line Stripers Pavement Marking Equipment 63 Use of laser based measurement equipment 21 7 Grinding new pavements 22 8 Concrete pavement maintenance 23 9 Low noise diamond grinding 24 10 Grinding concrete pavements in tunnels 27 11 References 27 List of Figures Figure 1 View of a diamond grind machine with a nominal 12m wide grinding drum used on road pavements in Technical Guide Grinding Concrete PavementsEQUIPMENT Grinding shall be done using diamond blades mounted on a selfpropelled machine designed for grinding and texturing pavement The equipment shall be a minimum 35,000 pounds, including grinding head, and of a size that will grind a strip at least 3 feet wide The effective wheel base of the machine shall be no less than 12 feet The effective wheel base is IGGA Guide Specification Diamond Grinding Asphalt

Conventional Diamond Grinding Pavement Preservation IGGA

for grinding and texturing pavement The grinding equipment shall be at a minimum 35,000 pounds including the grinding head, and of a size that will grind a strip at least 3 feet wide The effective wheel base of the machine shall be no less than 12 feet The effective wheel base is defined as the distance from the front wheel assembly transverse pivot point to the transverse GRINDING CONCRETE PAVEMENT 3521 Description Grind existing concrete pavement in the areas designated on the Plans Grind new concrete pavement the full width of the travel lanes Do not grind shoulders unless indicated in the Plans or required to promote drainage 3522 Equipment Provide a power driven selfpropelled machine that is specifically designed to SECTION 352 GRINDING CONCRETE PAVEMENTDiamond Grinding Equipment Diamond Grinding Process Diamond Grinding Final Surface Operating Grinding Machine Important Aspects of Operation: Grinding head blade setup Grinding head power Machine speed Steering Diamond Grinding Texture Dimensions Diamond Grinding Width of diamond blades (125 inches Land area 080 inches for hard Diamond Grinding Asphalt Pavement for Improved Performance

Grindlazer Scarifiers Graco

GrindLazer Graco’s line of GrindLazer equipment provides a complete set of solutions for surface preparation scarifier applications so you get the job done right in less time and with less effort Find A Distributor Contact SalesEQUIPMENT FOR GRINDING Grinder Hog Applications Grinding 1 / 9 Hog Technologies manufactures multipurpose machines that can grind pavement markings, cut grooves for inlaid pavement markings and cut rumble strips, plunge cuts, banana cuts and sinusoidal cutsGrinding The HogTBG134 Bridge Deck Groover PC1504 Pavement Grinder Groover PC6004EC Highway Grinder PC4504 Groover Grinder CG1 Mini Groover/Grinder CG3R Pavement Groover CG2 MiniGroover/Grinder BG249DT4 Grinder Groover 8 Item (s)Grinding Grooving Sawing Products

road,soil stabilizer,cold planer, asphalt,concrete

At RMM, we also manufacture high quality wear parts for all our soil stabilizer equipment and pavement milling machines We have our own where all our products are designed and manufactures Latest News About asphalt pavement repair and milling should know Asphalt milling is the process of removing the part or most of the old or Read More » Best Practices pavement grinding equipment Transline carries a wide range of pavement marking equipment to suit your purposes Either start out small with handheld heat and epoxy guns or “go big” with our selection of riding stripers And if you need to prep a work area, we have got you covered, as well, with our selection of grinders and scarifiers We are a professional pavement grinding equipment aremacdeEQUIPMENT Grinding shall be done using diamond blades mounted on a selfpropelled machine designed for grinding and texturing pavement The equipment shall be a minimum 35,000 pounds, including grinding head, and of a size that will grind a strip at least 3 feet wide The effective wheel base of the machine shall be no less than 12 feet The effective wheel base is IGGA Guide Specification Diamond Grinding Asphalt

SECTION 352 GRINDING CONCRETE PAVEMENT

GRINDING CONCRETE PAVEMENT 3521 Description Grind existing concrete pavement in the areas designated on the Plans Grind new concrete pavement the full width of the travel lanes Do not grind shoulders unless indicated in the Plans or required to promote drainage 3522 Equipment Provide a power driven selfpropelled machine that is specifically designed to Penhall’s corrective and profile grinding services reliably correct pavement that has been found to be out of spec, or which has experienced a failed ride test For clients that need surface testing or retesting, Penhall owns and operates profile testing equipment that uses the latest in pavement surface testing laser technology After the testingforride is performed, our highly Concrete Grinding Grooving PenhallDiamond grinding (DG) removes a thin layer at the surface of hardened PCC pavement using closely spaced diamond blades DG used to be an expensive operation; however, new, highproduction equipment as well as improved synthetic diamonds for saw blades made DG a more cost competitive option for PCC pavement rehabilitation DG has not been extensively used Pavement Manual: Diamond Grinding Texas Department of

Texturing Concrete Pavement for Reduced Tire/Pavement

4 EQUIPMENT 41 Diamond grinding shall be performed using diamond blades mounted on a selfpropelled machine designed for diamond grinding and texturing concrete pavement The equipment shall be at a minimum 35,000 pounds including the grinding head, and of a size that will grind a minimum width of 4 feet in a single pass The equipment shall Diamond Surface, Inc sets the standard for excellence in Heavy Highway Construction of diamond grinding, rumble stripping and concrete pavement restoration Members of International Grooving and Grinding Association, Concrete paving Association and Diamond Grinding Concrete Pavement RestorationFor the removal of pavement special markings stop bars, crosswalks, symbols and legends we have several portable ride on grinding machines Our highly productive machines make special marking removal quick and keep traffic moving Grinder Truck Truck mounted grinders are technologically advanced We have several grinder trucks available to meet the needs of any Equipment PK Contracting

PCC Pavement Rideability South Carolina Department of

EQUIPMENT 31 Diamond Grinding 311 Use only a selfpropelled grinding and texturing machine with diamond blades mounted on a multiblade arbor with a minimum cuttinghead width of 36 inches Equipment that causes strain or damage to the underlying surface of the pavement is not acceptable Repair or replace any equipment that causes excessive ravels, Grinding and grooving at speeds up to 8 MPH (1287 KPH) with full debris recovery Rumble Hog 3in1 machine for Grinding, Grooving, and Rumble Strips explore all Grinding, Grooving Rumbling equipment close Surface Hog 7,250 PSI (499 BAR) @ 79 GPM (299 LPM) 610 gal (2,309 liter) fresh water tank, 132 gal (499 liter) debris tank Blasting width 36" (914 cm) Home [waterblastingtechnologies]