roller press in cement mill r

2023-09-26T22:09:20+00:00

Cement Roller Press, Roller Press In Cement Plant AGICO

As newtype and energyefficient cement grinding machine, cement roller press has advantages of energysaving, high efficiency, less steel consumption and less noise Both apply for new cement plant building and old cement plant revamping According to the data, roller press helps ball mill system to increase the output by 3050% The 008mm fine material in Operating principle of Hydraulic Roller Press The feed material (cement clinker, slag or other cement raw material) is supplied to the roller press through inlet and here it is directed down between the two rollers which rotate against each other At the same time, the movable roller is forced towards stationary roller at a fixed hydraulic pressure The hydraulic force is being Optimisation of Roller Press Frame in Cement IndustryThe cement pregrinding system The most noticeable feature of the roller press cement pregrinding system is that the fine material power ground at the middle part of the roller will be sent to the ball mill for further grinding The cement grinding process in this system is rather simple with less equipment requiredBall Mill Roller Press Systems for Cement Grinding

Hydraulic Roller Press in Cement Plants AGICO Cement

The cement roller press is a type of material crushing machine which is often used in cement plants It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production efficiency, and Roller Press Raw Mill In Cement sovicanl Roller press configuration two solid crushing roller roller surface surfacing of roller surfaceor stud roller surface suitable for feed grain size is less than 40mm finished product sizerequirements of 4 15mm following finely homeworkAs the cement plant industry mill pre brokencement clinker limestone and composite material pre Roller Press In Cement Mill alromfrWhy install Roller Press in Cement Manufacturing Plant The overall trend is to increase the capacity of pregrinding bed, and transfer 60% to 70% of of the ball mill functions section to it and high fine airflow classification equipment to complete the system, with a large range of increased production and power saving capacityRoller press install for pregrinding before cement ball mill

Hydraulic Roller Press SINOMALY

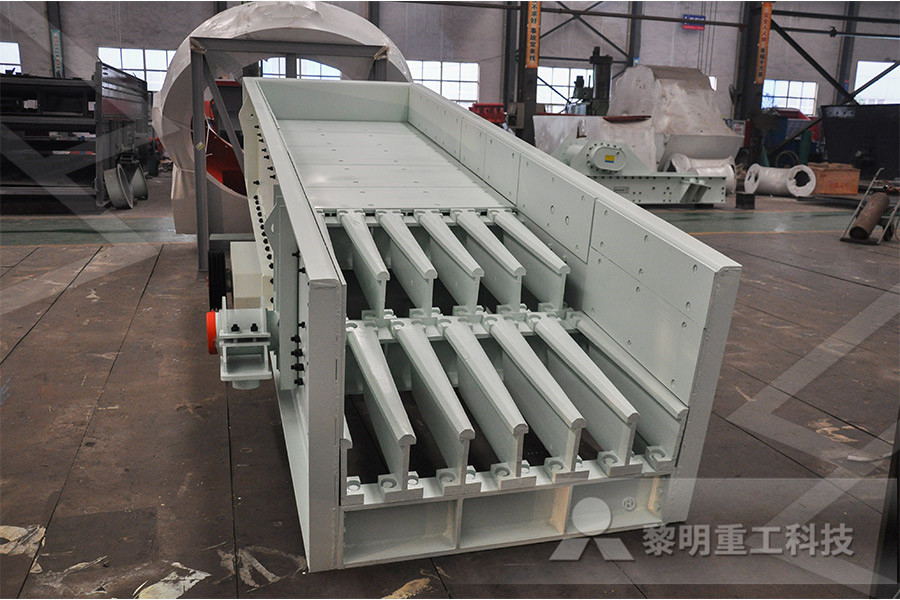

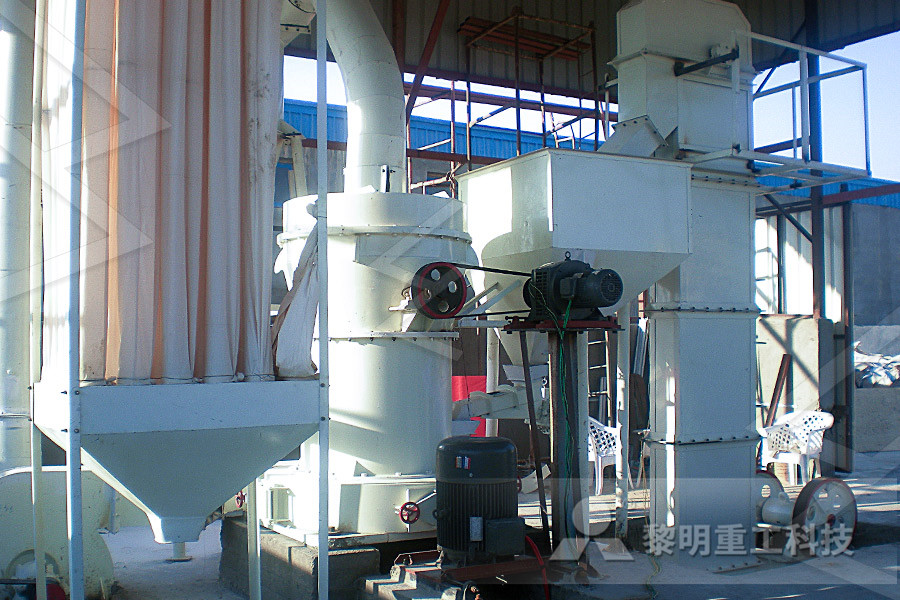

Hydraulic Roller Press (HRP) The roller presses manufactured by SINOMALY are used for cement grinding Compared to the pregrinding systems including ball mills with high energy consumption and low efficiency, these cement mill roller presses consume less energy and produce lower noise This roller press can improve the grinding capacity by 50 The cement grinding machine includes cement dryer, cement ball mill, cement roller press, powder selecting machine, conveyor and other cement equipmentWe can provide scheme design for free according to the requirements of users, and offer appropriate equipment to ensure Get Price; cold roller press machine ( Page 2 ) offers from cold 37 cold roller press Roller Press In Cement MillRoller press configuration two solid crushing roller roller surface surfacing of roller surfaceor stud roller surface suitable for feed grain size is less than 40mm finished product sizerequirements of 4 15mm following finely homework As the cement plant industry mill pre brokencement cli nker limestone and composite material; pre crushing grinding steel slag iron roller press mill in cement uf1fr

Foundation for roller press in a cement plant A case study

The paper describes roller press structure in a cement mill of a cement plant When provision of press is planned along with mill building, it is possible to provide suitable structural arrangement This provision is sometimes made in an existing mill or in mill structure already under construction In such a case, limitations are imposed on planning of supporting structure 22/08/2020 Roller Press + Ball mill circuit for Cement production Higher grinding plant process availabilityAcceptability of Roller press combination with Ball mill Roller Press + Ball mill circuit for Cement production Roller Press In Cement Mill Roller Press Cement Mill Roller press at cement mill manual stone crusher machine OK mill The higheffiency and reliable roller mill for cement and slag grinding OK Mill a Unique design with a drill press and machining on a mill used concrete block making machine for sale mobile concrete crusher for sale rock crusher 250 ton per hour Roller Press In Cement Mill neuvillefootfr

Roller Presses KHD International

Roller Presses: rollers, surfaces Reduced wear by autogenous wear protection Grinding Rolls KHD Humboldt Wedag Roller Presses offer rollers with appropriate wear protection for almost all applications in the cement and minerals industry The twopart roller consisting of shaft and tire allows for economical surface replacement, single part Hydraulic Roller Press (HRP) The roller presses manufactured by SINOMALY are used for cement grinding Compared to the pregrinding systems including ball mills with high energy consumption and low efficiency, these cement mill Hydraulic Roller Press SINOMALYroller press in cement mill The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons KHD Roller Presses offer a reliable solution for every application for grinding cement slag raw material or for special applications such as preparation of ore Chat Online Products Show Roller Press – LNV roller press in cement mill mobilisticode

Roller Press + Ball mill circuit for Cement production

22/08/2020 Roller Press + Ball mill circuit for Cement production Higher grinding plant process availabilityAcceptability of Roller press combination with Ball mill The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new The Hydraulic Roller Press offers costsaving grinding Roller Press In Cement Mill Cement clinker pregrinding roller pressDescription of our roller mill pregrinding system for cement plant our roller mill is a kind of newtype cement grinding equipment developed on the basis of advanced technology, and its grinding system has integrated the rolling, scattering, separting, drying and powder separating into one bodyRoller Press In Cement Mill twodotobe

roller press for cement mill aplomb24fr

Roller Press At Cement Mill ManualADR tube mills manufacturers,tube mill line suppliers ball tube mill presenting ball tube mill of open circuits and air swept for coal and cement grinding these mills 06/09/2017 Roller presses have proven to be a popular option for new and old cement plants in recent years When used in a production line upgrade with a ball mill, they increase throughput and energy efficiency Roller presses compact the material through two horizontal rolls One roll is fixed, while the other is connected to a hydraulic system to Finding failure International Cement ReviewVertical cement mill is consists of the separator rotation system, separate, the upper shell is equipped with the access door and feeding inlet, the roller device, transmission, rod mill, a seal, friction ring, discharge ring, mill regulating device, the wind ring regulating device, roller pressure system, guide rail protection, tie rod sealing device, bearing seal gas supply part, feeding oil Vertical Cement Mill, Vertical Roller Mill Buy Cement

Roller Press In Cement Mill Manual VCharty Roll Crusher

Raw mill loesche vrm 375 tph khd roller press 3 275 tph coal mill loesche vrm 40 tph pfeiffer vrm 90 tph kiln flsmidth slc ilc conversion of coal mill amp cement mill esp to bag house to reduce emissions to 20 mgnm3 cii energy benchmarking manual 2018, version 30Cement Mill, Clinker Mill We provide various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily Cement Mill, Clinker Mill SBCCOCEMENT