working of a jaw crusher r

2022-11-08T16:11:16+00:00

Jaw Crusher Working Principle – StudiousGuy

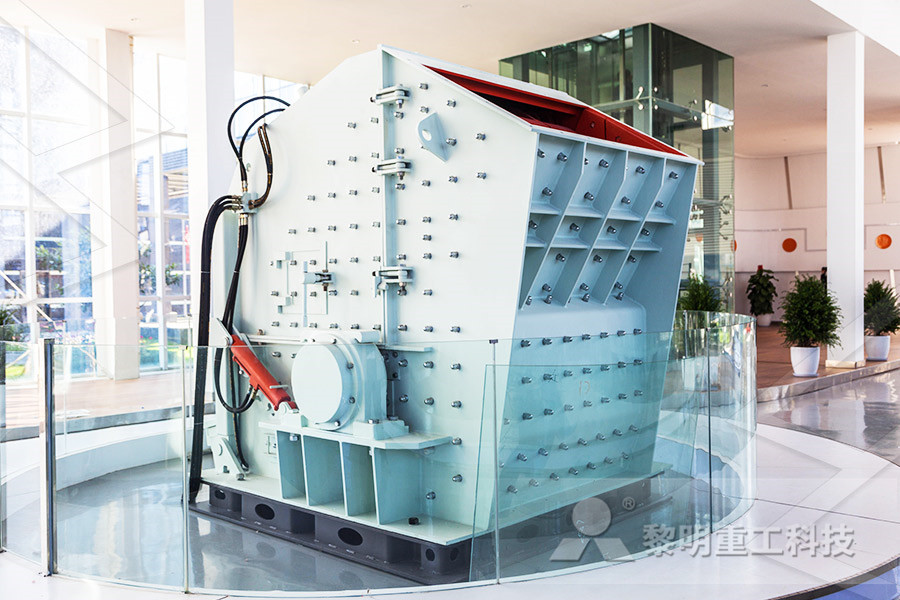

A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws into smaller piecesWorking part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or slightly upper camber) fixed in the front wall of the body, and the other is movable jaw plate (moving jaw), location inclined to form the next big small crushing chamber (working chamber) and the fixed jaw Jaw Crusher Working PrincipleJaw Crusher Working Principle Gravel Mill25/12/2014 The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamberThe Working Principle Of A Jaw Crusher Editors Top

working of jaw crusher sremachineries

Jaw Crusher Working Principle Jaw crusher is widely used in industrial and mining enterprises this is because the aircraft structure is relatively simple and has a large range of models Jaw crusher is mainly used as the primary crusher It can be used with mineral processing equipment gravel ancillary equipment it also can be used alone Get Price Jaw Crusher Working 01/04/2008 china This jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt andThe Working Principle of Jaw Crusher YouTubeThe working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jawsWhat is a Jaw Crusher? – MEKA Crushing Equipment

What is a Jaw Crusher Advantages, Types, Parts and

The working principle of jaw crushers: When working, the motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate closer to the fixed jaw plate, and the material passes through the two jaws Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but the aggregates have a more elongated formJaw Crusher an overview ScienceDirect TopicsJaw Crusher Working Principle A series of jaw stone crushers use compressive and squeezing force for reducing materials This physical force is created by the two jaw plates, one of which is a movable plate and another is fixed, both of them are made of manganeseJaw Crusher Primary Crusher in Mining Aggregate JXSC

Jaw Crusher Working Principle – StudiousGuy

Working of a Jaw Crusher The material to be broken with the help of a jaw crusher is fed between the two mechanical jaws The fixed jaw, as the name suggests, is stationary and does not get displaced from its original position The main task of the fixed jaw of the jaw crusher is to hold the material to be crushed in place so that it does not slip when the force is applied The 25/12/2014 The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamber The The Working Principle Of A Jaw Crusher Editors TopJaw Crusher Working Principle Jaw crusher is widely used in industrial and mining enterprises this is because the aircraft structure is relatively simple and has a large range of models Jaw crusher is mainly used as the primary crusher It can be used with mineral processing equipment gravel ancillary equipment it also can be used alone Get Price Jaw Crusher Working working of jaw crusher sremachineries

What Are Jaw Crushers and How Do They Work? OreFlow

28/03/2019 A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarry industries as well as in recycling processes where Jaw crusher is the first crushing machine of sand and gravel crushing production line so the efficiency of jaw crusher is directly related to the productivity of the whole production line How to improve the working efficiency and reduce the failure rate of jaw crusher is very important In terms of equipment operation and maintenance operators should do a good job in the normal working of a jaw crusher sarlblissonfrJaw Crusher Working Principle A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is Jaw Crusher: Range, Working Principle, Application

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

These design tweaks over time have perfected a machine that’s simple enough in its working principle that it may never truly become obsolete Today, two main jaw crusher configurations are what you will see from the major equipment manufacturers They differ based on how the swing jaw moves, though their output is similar Double Toggle – Blake Type or Overhead Pivot 28/08/2021 Just like other stone crusher machines, jaw crusher also needs a regular repair and maintenance after a certain time of working, or it will get decreased service life because of severe wear of important partsThe Most Practical Jaw Crusher Repair and Maintenance The working principle of a jaw crusher is: the motor drives the belt and the pulley to move the jaw up and down through an eccentric shaft; when the jaw rises, the angle between the toggle and the jaw expands, thus pushing the jaw plate closer to the fixed jaw plate, at the same time, the material is crushed; when the jaw goes down, the angle between toggle and jaw reduces; Jaw Crusher for Sale Large Jaw Crusher Machines for

Jaw Crusher Animation YouTube YouTube

29/07/2013 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Working of a Jaw Crusher The material to be broken with the help of a jaw crusher is fed between the two mechanical jaws The fixed jaw, as the name suggests, is stationary and does not get displaced from its original position The main task of the fixed jaw of the jaw crusher is to hold the material to be crushed in place so that it does not slip when the force is applied The Jaw Crusher Working Principle – StudiousGuyThe jaw crusher is simple in structure, easy to manufacture and reliable in operation The working part of the jaw crusher consists of two jaws, one is a fixed jaw (fixed jaw), which is fixed vertically (or slightly inclined at the upper end) on the front wall of the machine body, and the other is a movable jaw (moving jaw) It is inclined to form a crushing cavity (working cavity) with a WORKING PRINCIPLE OF JAW CRUSHER

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

These design tweaks over time have perfected a machine that’s simple enough in its working principle that it may never truly become obsolete Today, two main jaw crusher configurations are what you will see from the major equipment manufacturers They differ based on how the swing jaw moves, though their output is similar Double Toggle – Blake Type or Overhead Pivot Jaw Crusher Working Principle StudiousGuy Working Principle of a Jaw Crusher A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws explain the working principle of jaw crusherProcedure Of Working And Use Of Jaw Crusher Equipment Procedure of working and use of jaw crusher equipment for remotely controlled methods are recommended for clearing blocked jaw crushers and if manual methods are to be used a comprehensive assessment of the risks is essential rules and safe operating procedures should be established for each task and the Working Pocedure Of A Jaw Crushersjaw Crusher

How to improve the Working Efficiency of Jaw Crushers

04/12/2020 Jaw crusher plays a very important role in sand making production line It can break large rocks into small pebbles with smaller grain size, which is convenient for subsequent sand making Therefore, to improve the working efficiency of jaw crusher can enhance the production capacity of the whole production lineJaw Crusher Price Jaw Crusher Working Principle Jaw crusher pricehe jaw crusher is abruptly broken, and it is an early crushing equipmentecause of its simple structure, firmness, reliable work, easy maintenance and overhaul, and relatively low production and construction costs, it is still widely used in metallurgy and chemical industry until nowConstruction And Working Of A Jaw CrusherThe Working Principle Of Jaw Crusher Jul 24 2012 The working principle of jaw crusher 1 The Working Principle of Jaw Crusher Jaw crusher consists of many parts like eccentric draft frame large belt wheelmobile jaw flying wheel toggle plate toggle plate gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks gravelrock dust Working Of A Jaw Crusher judithinontwikkelingnl

construction and working of a jaw crusher

Construction And Working Of Jaw Crusher Wikipedia RobuSt ConStRuCtion The jaw crusher is a single toggle jaw crusher, aspect in the crushing process Our mission is to work together with our customers to Get More; Jaw Crushers, How Do They Work? Mine Pilot Crushtec International (Pty) Ltd supplies a full range of cost effective, heavy duty, fit for 17/02/2016 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and Working Principle of Crushers