hightensity wet drum magnetic separator r

2022-03-14T00:03:46+00:00

Hightensity Permanent Drum Magnetic Separator

25/09/2006 Wet Drum Permanent Magnetic Separator is suitable for Mine, Coal preparation plant etc use weak wet magnetic field to sort out the strong magnetic ore, or eliminating the strong magnetic minerals mixed in nonmagnetic minerals The magnetic field of CTSN,B wet drum permanent magnetic separators divide into rotary and fixedHightensity Wet Drum Magnetic Separator Magnetic material is the most important part of high intensity wet drum magnetic drum separator longi uses high coercive force and high class ndfeb rare earth super strength magnet magnet is of high coercive force and rare earth super strength magnet is coated chrome which makes sure the demagnetization less than 3 in 10 Hightensity Wet Drum Magnetic SeparatorIntroduction Wet Drum Magnetic Separator aka Wet Drum Separator can be used for recovery of fine and strong magnetic minerals or removal of small amounts of ferromagnetic materials from nonmagnetic minerals Drum Magnetic Separator is suitable for beneficiation of magnetite, pyrrhotite, hematite, limonite, siderite, etc GTEK offers three different tank styles to meet Wet Drum Magnetic Separator GTEKmagnet

Wet Drum Separators Eriez

The Eriez Wet Drum Magnetic Separators is engineered and fabricated to provide reliable operation in demanding applications The separator is designed for the continuous treatment of coarse milled ore providing a high level of availability The tank and drum are fabricated from heavy gauge stainless steel with wear plate in impact areasOur STEINERT wet drum magnetic separators are used in the fine grain range from 1 µm up to 3000 µm (0001 mm – 3 mm) to separate magnetic particles from process liquids, sludges or emulsions Their strong magnetic fields enable the efficient separation of magnetite or ferrosilicon from the wet mediumWet drum magnetic separator for separating finegrained Wet Drum Magnetic Separator: Working Principle When ferrous material is put to the drum surface, a magnetic field is created, which draws the ferrous material to the outer drum which is revolving Because of this action, a selfcleaning action is created by continuously conveying the captured ferrous material out of the product flow to the ferrous discharge region Feature, Everything You Should Know About Wet Drum Magnetic Separator

Wet Drum Permanent Magnetic Separator Manufacturer

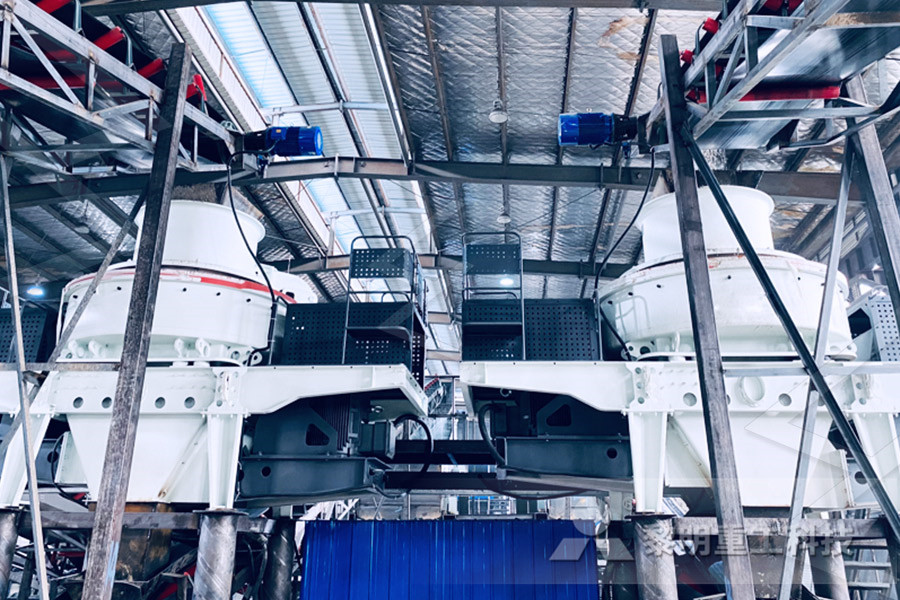

The wet drum separator is intended for use in the metal processing industry and for the treatment of preconcentrates extracted from the high gradient magnetic filter In wet drum separator, around 90% of the grain sizes ranging from 1 µm to 1000 µm can be separated as sludge Actual Product Images:The Wet Drum Magnetic Separator features a strong, stationery permanent magnetic element mounted inside a revolving nonmagnetic shell The adjustable multipole ceramic ferrite magnetic element produces a highflux, radial magnetic field (ie, along the circumference of the shell), which maximises recovery to +999% The main stainlesssteel cover of the Wet Drum Wet Drum Magnetic Separators Bunting RedditchEriez Wet Drum Separators The Eriez Wet Drum Magnetic Separators is engineered and fabricated to provide reliable operation in demanding applications The separator is designed for the continuous treatment of coarse milled ore providing a high level of availability The tank and drum are fabricated from heavy gauge stainless steel with wear plate in impact areas Wear High Intensity Wet Drum Magnetic Separator

Wet High Intensity Magnetic Separators Multotec

Wet High Intensity Magnetic Separators (WHIMS) from Multotec combine magnetism, matrix rotation and gravity to paramagnetic materials Applications include heavy minerals, ilmenite, manganese and iron ore (haematite) beneficiation; PGM upgrading as well as manganese recovery from slimes dams This offers innovative new approaches and technology for solving Wet Drum Magnetic SeparatorQijin Magnet Co, LtdWet permanent Drum Magnetic Separator are used in Dense Media Separation (DMS) plants for the recovery of magnetic particles from the dilute medium They must recover the maximum amount of magnetic particles at the highest possible density Wet drum magnetic separator consists of a stationery Wet Drum Magnetic SeparatorQijin Magnet Co, LtdGood quality high intensity wet drum magnetic separator from high intensity wet drum magnetic separator manufacturer, Buy high intensity Buy high intensity wet drum magnetic separator, Good

Wet Drum Permanent Magnetic Separator Manufacturer

The wet drum separator is intended for use in the metal processing industry and for the treatment of preconcentrates extracted from the high gradient magnetic filter In wet drum separator, around 90% of the grain sizes ranging from Wet Drum Magnetic Separator processing heavy solutions from flotation or sink/float separation, iron beneficiation through to the cleaning of process of water from degreasing baths or coolants The processing objective is recovery of valuable iron particles and the avoidance of disruptive iron particles Working Principal The liquid flows through a semicircular separating Wet Drum Magnetic Separator Galaxy MagneticsThe Magnetic Wet drum separator is used for the separation of iron deposits from sand / silt flows Used during sand reclamation and for cleaning of contaminated soil The sludge flow is distributed through an inlet tank and flows underneath the Magnetic drum, ferrous particles are attracted to the magnet and separated from the sludge The cleaned sludge flow proceeds to Magnetic Wet drum separator Bakker Magnetics, delivering

Magnetic Separators – Wet Drum WPE Process Equipment

Wet drum magnetic separators fitted with rare earth magnetic elements are necessary for lesser magnetically susceptible minerals ie Martite containing a Manganese inclusion Description All Eriez Magnetic’s Wet Drum Magnetic Separators operate on the same basic principle of a drum rotating around shaft mounted, permanent magnetic elements encased in BAS high intensity electromagnetic filters are preferred of the seperation magnetic impurities (ferro magnetics and paramagnetic materials) from nonmagnetic ores and raw materials It provides maximum opportunity for the separation of materials with low magnetic susceptibility (ilmenite, biotite, chromite, hematite, etc) at 15 – 20 Tesla effective magnetic field intensity Wet High Density Magnetic Filters BAS®•Wet drum magnetic separators •Induced roll magnetic separator Magnetic field gradient, fractions 12 Magnetic pulleyj • Setr of stationary magent cover 50 to 75% of drum circumference Magnetic material, under the action of magnetic field, adhjere to the drum or pulley and move along the pulley as long as the particles remain in the magnetic field and non MECHANICAL SEPARATION TECHNIQUES

high intensity wet drum magnetic separator

Wet Magnetic Drum Separator 911Metallurgist Lowintensity separators are used to treat ferromagnetic materials and some highly paramagnetic minerals Minerals with ferromagnetic properties have high susceptibility at low applied field strengths and can therefore be concentrated in low intensity (~03T) magnetic separators For lowintensity drum Eriez Wet Drum Separators The Eriez Wet Drum Magnetic Separators is engineered and fabricated to provide reliable operation in demanding applications The separator is designed for the continuous treatment of coarse milled ore providing a high level of availability The tank and drum are fabricated from heavy gauge stainless steel with wear plate in impact areas Wear High Intensity Wet Drum Magnetic SeparatorWet Drum Magnetic SeparatorQijin Magnet Co, LtdWet permanent Drum Magnetic Separator are used in Dense Media Separation (DMS) plants for the recovery of magnetic particles from the dilute medium They must recover the maximum amount of magnetic particles at the highest possible density Wet drum magnetic separator consists of a stationery Wet Drum Magnetic SeparatorQijin Magnet Co, Ltd

Magnetic Separators – Wet Drum WPE Process Equipment

Wet drum magnetic separators fitted with rare earth magnetic elements are necessary for lesser magnetically susceptible minerals ie Martite containing a Manganese inclusion Description All Eriez Magnetic’s Wet Drum Magnetic Separators operate on the same basic principle of a drum rotating around shaft mounted, permanent magnetic elements encased in Good quality high intensity wet drum magnetic separator from high intensity wet drum magnetic separator manufacturer, Buy high intensity Buy high intensity wet drum magnetic separator, Good Manufacturer of Drum Type Magnetic Separators Wet Drum Magnetic Separator, Inline Drum Type Magnetic Separator, Drum Magnetic Separator and Single Drum Magnetic Separator offered by Shyam Magnet, Rajkot, Gujarat Shyam Magnet Near Sorathiyawadi circle, Rajkot, Gujarat GST No 24APBPR9614P1ZB Call 69% Response Rate Send Drum Type Magnetic Separators Wet Drum Magnetic

Wet Drum Magnetic Separator Galaxy Magnetics

Wet Drum Magnetic Separator processing heavy solutions from flotation or sink/float separation, iron beneficiation through to the cleaning of process of water from degreasing baths or coolants The processing objective is recovery of valuable iron particles and the avoidance of disruptive iron particles Working Principal The liquid flows through a semicircular separating Dense Media Separation Wet drum magnetic separators are used extensively in dense media separation to recover mineral used as a flotation medium ie magnetite ferro silicon Details Drum Magnet Magnetic Separator Bunting Redditch This not only enhances the Drums performance but also reduces the magnetic fields in the shaft and bearings helping to High Intensity Wet Drum Magnetic SeparatorEstablished in 1996, XINGGUANG is one of the most professional wet drum separators manufacturers and suppliers in China Welcome to buy discount wet drum separators for sale here from our factory All customized equipment made in China are with high quality and competitive priceChina Wet Drum Separators Suppliers, Manufacturers

Wet low intensity magnetic separators

The range of wet magnetic separators is composed of the series WS1200 with drum diameters of 1200 mm with a magnetically effective drum length up to 3678 mm in increments of 613 mm The WS1200 series includes concurrent, countercurrent and counterrotation tank designs The wet magnetic separators are primarily used for cobbing, roughing, cleaning and finishing