ball grinder mill and classifying production line r

2020-11-17T18:11:59+00:00

ball grinder mill and classifying production line

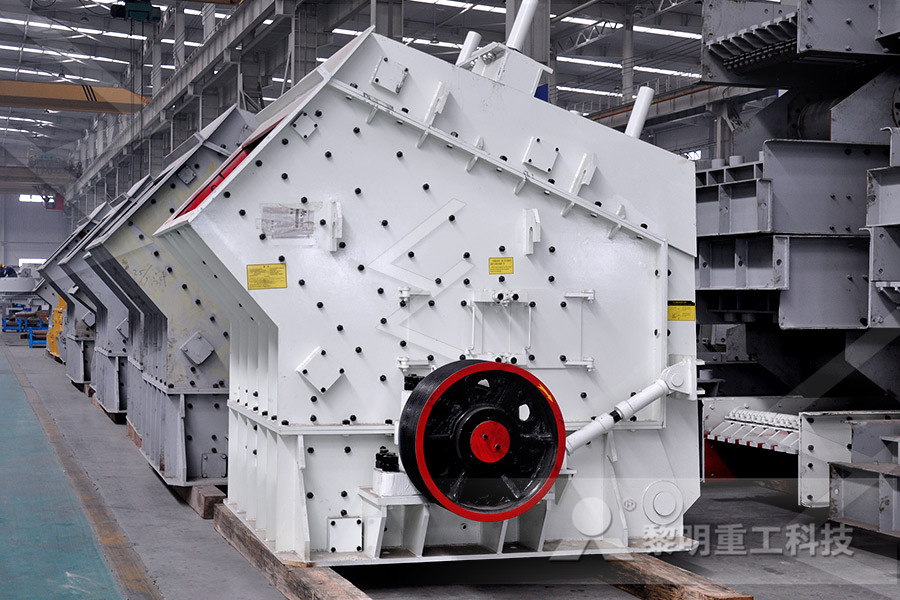

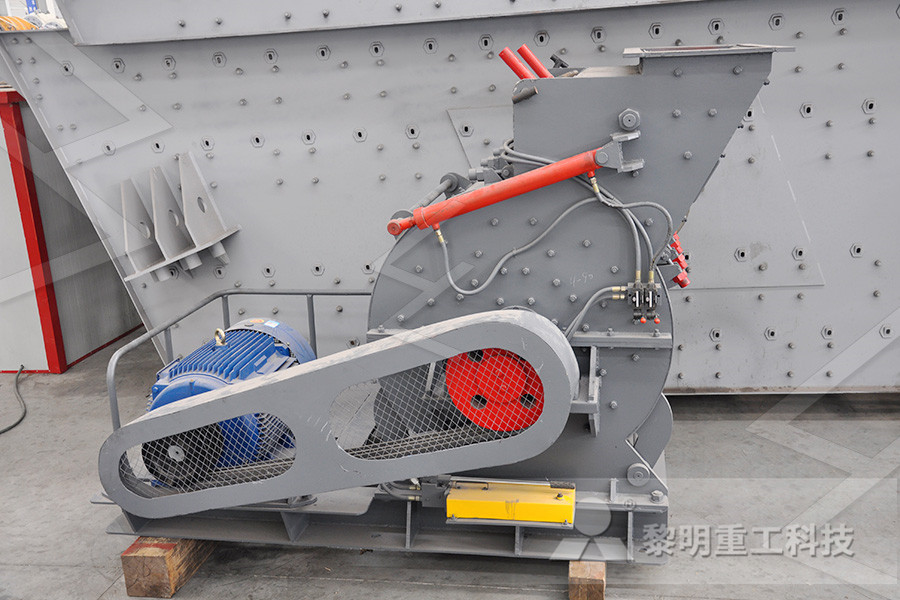

ball grinder mill and classifying production line the process mainly includes crushing (usually using twostage crushing), grinding, grading, packaging, bin, conveying, lifting and so on ball mill can be connected with multiple classifiers for parallel classifier, can also connected with multiple series classifier, simultaneously produce multiple sizes productsBall Grinder Mill And Classifying Production Line Ball Mill Ball Mill is selected on the basis of hardness, grindability index of material, feed size, product size, capacity Right selection of grinding ball and rod can improve grinding efficiency and reduce energy consumption Classifier Different series of classifier could be selected Ball Grinder Mill And Classifying Production Lineball grinder mill and classifying production line Our products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentOur leading products have crushing equipment, sand making equipment, mobile crusher, etc, Each type of product is with complete specifications All products have passed ball grinder mill and classifying production line

Ball Mill and Classifying Line ALPA Powder Equipment

Ball Mill and Classifying Line The product particle size control is flexible, special design is adopted to reduce noise and emission Automatic control, easy to operate According to the scale of investment, it provides personalized customized scheme and provides valueadded services It is widely used in calcium carbonate (calcite, marble Ball Mill and Classifying Production Line Classifying Ball Mill Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce ball grinder mill and classifying production lineBall Grinder Mill And Classifying Production Line The LHMB Ceramic Media Ball Mill Classifying Production Line is the best solution and specifically design for high purity material grinding liner and grinding media adopt corundum cobblestone quartz zirconia according to the material requestBall Grinder Mill And Classifying Production Line

ball grinder mill and classifying production line Escort

ball grinder mill and classifying production line Ball Mill and Classifying Production Line Product Size: D90: 2~45μm Production Capacity: 1~20t/h Get Price List Chat Online GET A QUOTE Note: If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days We promise that all your informations won't be Ball Mill and Classifying Production Line Classifying Ball Mill Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball millball grinder mill and classifying production line,Classifying and Ball Mill Production Line; Classifying and Ball Mill Production Line D50: 345 μm Available granularity 30% Reduced energy consumption 76dB(A) Noise The world’s leading technology, mature technology, stable operation, low maintenance cost, low unit energy consumption, flexible selection of grinding media and liners, highpurity processing, Classifying and Ball Mill Production Line Superfine

Classifying and Ball Mill Production Line – Products

Classifying and Ball Mill production line Return Virtual Showroom Unique Advantages World’s leading process line with mature technology, green, low energy consumption, reliable, leading, innovative, high value creation Automatic Control, Flexible control of product particle size With more than 100 EPC projects, ALPA has achieved ALPA’s ball mill classifying production line, ball mill and classifier work well together, can complement each other, high efficiency, large output, stable operation and stable product quality Influencing factors of Ball mill output Feeding particle size and distribution; Scientific calculation of the length to diameter ratio of the mill; Speed of the ball mill and motor power of the mill Classifying and Ball Mill Production Line ALPA Powder Ball Mill Classifying Production Line Manufacturers, Factory, Suppliers From China, Our company has already set up a professional, creative and responsible team to develop clients with the multiwin principleBall Mill Classifying Production Line

Ball Grinder Mill And Classifying Production Line

Ball Grinder Mill And Classifying Production Line Ball Mill Ball Mill is selected on the basis of hardness, grindability index of material, feed size, product size, capacity Right selection of grinding ball and rod can improve grinding efficiency and reduce energy consumption Classifier Different series of classifier could be selected Ball Mill Classifying Production Line Manufacturers, Factory, Suppliers From China, We warmly welcome merchants from your home and overseas to contact us and set up business enterprise partnership with us, and we'll do our greatest to serve youBall Mill Classifying Production LineBall Mill Ball Mill Classifying Production Line CaCO3 Grinding Mill manufacturer / supplier in China offering 2 10um Heavy Calcium Carbonate Production Line Sodium Bicarbonate Ultrafine Grinding and Classifying Mill 6150um Particle Size Air Classifier for Fly Ash/Slag/Steel Slag and so on Read More Classifying and Ball Mill Production Line ALPA Powder German ball mill classifying production line boulangeriedespresfr

ball grinder mill and classifying production line

Ball Mill and Classifying Production Line Classifying Ball Mill Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce Coal Mill Production Line in Vietnam Project location: Vietnam Equipment: LM130M complete Carbon Black Grinding with 8021 in China Material: carbon black Model: 800 Capacity: Limestone Grinding with MTW175 Materiel: Limestone Working Hours: 24hours/day Finalball mill and classifying production lineBall Mill and Classifying Production Line The world’s leading technology, mature technology, stable operation, low maintenance cost, low unit energy consumption, flexible selection of grinding media and liners, highpurity processing, concentrated product Ball mill,ball milling,ball grinderALPA powder

Ball Mill and Classifying Line ALPA Powder Equipment

Ball Mill and Classifying Line The product particle size control is flexible, special design is adopted to reduce noise and emission Automatic control, easy to operate According to the scale of investment, it provides personalized customized scheme and provides valueadded services It is widely used in calcium carbonate (calcite, marble China Ball Mill Classifying Production Line catalog of 2500mesh 5um High Energy Worlds Leading 100kw Small Scale Mining Ball Grinder Mill for Limestone / Calcite, 2500mesh 5um High Energy Worlds Leading 100kw Cocoa Ball Mill provided by China manufacturer Shandong ALPA Powder Technology Co, Ltd, page2ball grinder mill and classifying production lineball grinder mill and classifying production line the process mainly includes crushing (usually using twostage crushing), grinding, grading, packaging, bin, conveying, lifting and so on ball mill can be connected with multiple classifiers for parallel classifier, can also connected with multiple series classifier, simultaneously produce multiple sizes productsball grinder mill and classifying production line

Classifying and Ball Mill Production Line Industrial

Advantages of Solid Waste Processing by Classifying and Ball Mill Production Line Fly ash can be ground and separatedgrade ash, ultrafine ash, specific surface area 4002000m²/kg; Fly ash can be separated and extracted from 245μm ultrafine beads, which can be used as rubber and plastic fillers instead of calcium carbonate;ball grinder mill and classifying production line Our products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentOur leading products have crushing equipment, sand making equipment, mobile crusher, etc, Each type of product is with complete specifications All products have passed ball grinder mill and classifying production lineBall Grinder Mill And Classifying Production Line The LHMB Ceramic Media Ball Mill Classifying Production Line is the best solution and specifically design for high purity material grinding liner and grinding media adopt corundum cobblestone quartz zirconia according to the material requestBall Grinder Mill And Classifying Production Line

Classifying and Ball Mill Production Line ALPA Powder

ALPA’s ball mill classifying production line, ball mill and classifier work well together, can complement each other, high efficiency, large output, stable operation and stable product quality Influencing factors of Ball mill output Feeding particle size and distribution; Scientific calculation of the length to diameter ratio of the mill; Speed of the ball mill and motor power of the mill Ball Mill and Classifying Production Line Classifying Ball Mill Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce ball grinder mill and classifying production lineBall Mill Classifying Production Line Quartz Grind Mill Process Characteristics 1 Design concept originated in the latest German technology is the international standard of nonmetallic mineral ultrafine processing production line 2 The choice of ball mill according to the character of material product size and production requirements using non standardized design to meet Ball Mill And Classifying Production Line

ball mill and classifying production line

Coal Mill Production Line in Vietnam Project location: Vietnam Equipment: LM130M complete Carbon Black Grinding with 8021 in China Material: carbon black Model: 800 Capacity: Limestone Grinding with MTW175 Materiel: Limestone Working Hours: 24hours/day Final