ball mill abrasive materials r

2020-09-08T20:09:44+00:00

Which material can grind with ball mill?

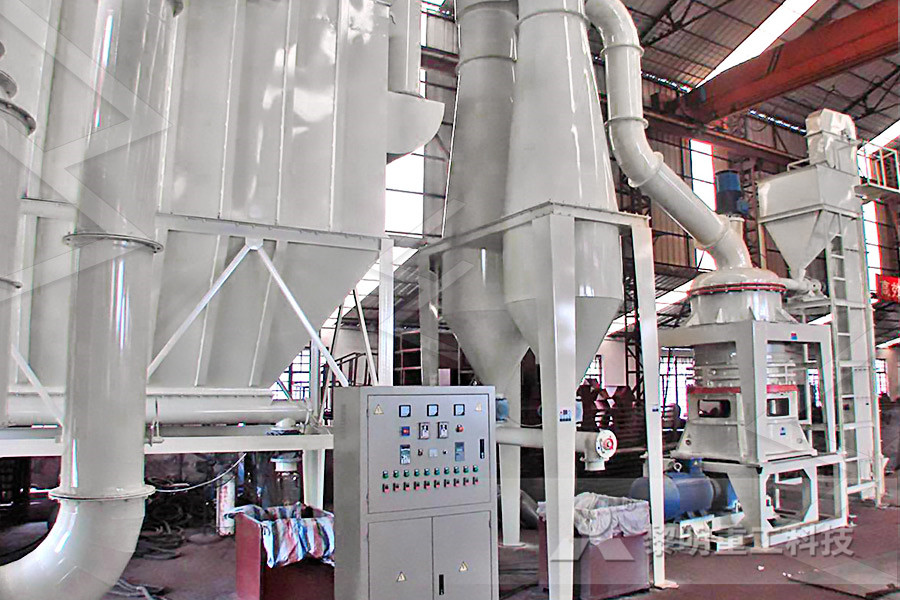

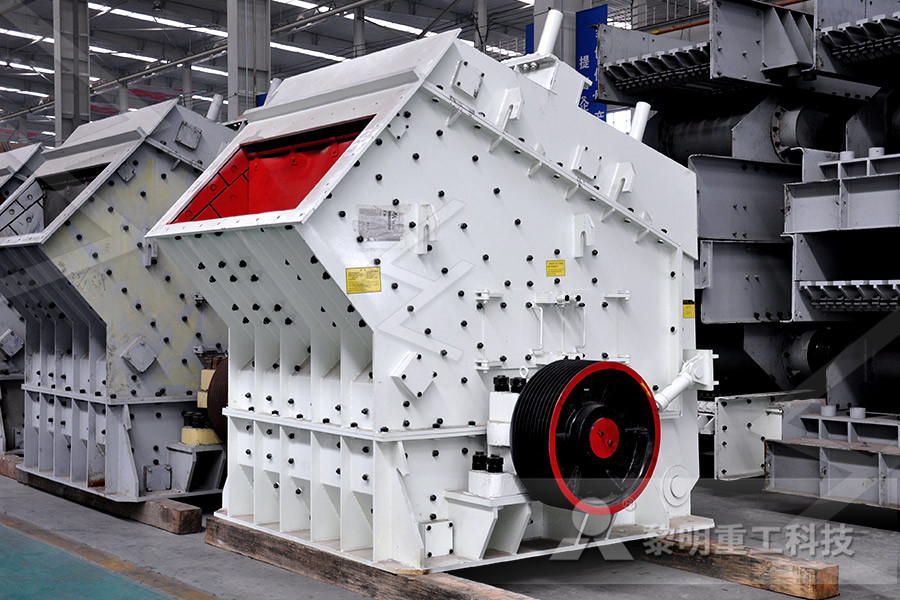

Introduction of Ball Mill The ball mill is the key equipment for crushing the material after it is broken This type of grinder is fitted with a certain number of steel balls in its barrel for abrasive media Ball mill in operation, Ball Mill steel Ball in the role of gravity, and constantly hit the mineral, continuous circulation, grinding to qualified finished productsIn fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials Advantages of the ball mill Adjustable grain size distribution When operating on the open circuit principle, the product fineness and grain size distribution are adjusted via the peripheral material dischargeBall mills for various applications Gebr Pfeiffer11/01/2016 Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used in a completely enclosed form 3 Has a wide application 4 It can be used for continuous operation 5 It is used in milling highly abrasive materialsBall Mill: Operating principles, components, Uses

Ball Mill Qingdao EPIC Powder Machinery

Ball Mill Product Description Due to low speed rotation, ball mills are ideal for hard and abrasive materials like Quartz and Zircon sandas well as for grinding soft minerals as Calcium Carbonateand Kaolin The mechanism of grinding takes place with minimum of impact and attrition energy, so ball mills are good for mass production of highquality powder Our ball 13/02/2017 BallRod Mills of the grate discharge type are made by adding the improved type of grates to a standard BallRod Mill These grates are bolted to the discharge head in much the same manner as the standard headlinersBall Mills Mineral Processing MetallurgyBall mills are commonly used for crushing and grinding the materials into an extremely fine form The ball mill contains a hollow cylindrical shell that rotates about its axis This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in itBall Mills an overview ScienceDirect Topics

grinding of abrasive materials in the mill,

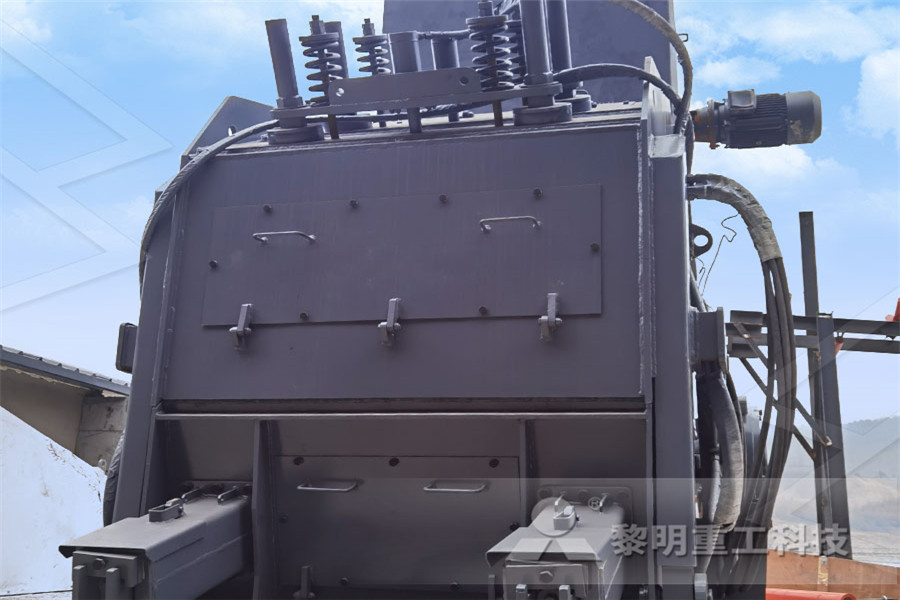

The impact of the ball mill grinding abrasive materials When the cylinder moderate speed, grinding has been elevated to a certain height the falling down, was "thrown down the state of motion", then grinding the materials have a greater impact and abrasive, grinding better In the Ball Mill, the number of grinding media filling fewer higher cylinder speed, the rolling and Ball Mills and other forms of tumbling mills such as Tube Mills, Rod Mills and Batch Mills form a significant type of equipment used for the size reduction of a wide variety of materials such as minerals, ores, coal, carbon products and general chemicalsBall Mill British RemaThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight Ball mills are employed in either primary or secondary grinding applications In primary applications Ball Mill an overview ScienceDirect Topics

(PDF) A comparison of wear rates of ball mill grinding media

The Ball Mill Abrasion (BMA) test was developed by th e University of Queensland Materials Performance group to simulate the h igh stress abrasion conditions experienced in production ball Introduction of Ball Mill The ball mill is the key equipment for crushing the material after it is broken This type of grinder is fitted with a certain number of steel balls in its barrel for abrasive media Ball mill in operation, Ball Mill Which material can grind with ball mill?abrasive materials wet ball millmining equiments supplier Vibration ball mill, also known as a vibrating ball mill or vibratory ball mill, is a kind of ball mill machine that uses the highfrequency vibration of the cylinder to make the grinding medium in the cylinder impact the material by inertial force Vibration ball mill is a new type of highefficiency and energysaving grinding abrasive materials wet ball millmining equiments supplier

Ball Milling Material Milling, Jet Milling AVEKA

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the 13/02/2017 A ball mill efficiently operated performs a wide Nowadays grinding mills are almost extensively used for comminution of materials ranging from 5 mm to 40 mm (3 /16″—1 5/8″) down to varying product sizes They Ball Mills Mineral Processing Metallurgy27/03/2015 Fine grinding abrasive materials is typically needed to create particle sizes in the minus 50 mesh range (297 microns) down to about 95% minus 325 mesh (45 microns) Some of these sizes are typically referred to as Different Approaches to Grinding Abrasive Materials

Ball Mill Principle, Construction, Uses, Advantage

17/08/2021 C Ball mill is an open system, hence sterility is a question D Fibrous materials cannot be milled by ball mill 10 What particle size can be obtained through ball mill? A 20 to 80 mesh B 4 to 325 mesh C 20 to 200 mesh D 1 to 30 mm ANSWERS:1 Both B and C 2 Optimum speed 3 Longitudinal axis 4 Both 5 A – 3 B – 4 C – 2 D – 1 6 Ball Mill Models Available in various sizes, typically in the range of 09m x 09m to 367m x 64m Applications Ball Mills and other forms of tumbling mills such as Tube Mills, Rod Mills and Batch Mills form a significant type of equipment used for the size reduction of a wide variety of materials such as minerals, ores, coal, carbon products and general chemicals Generally used in high Ball Mill British Remaabrasive and impact wear due to their large (75 – 100 mm) dia meters Ball mill balls experience a greater number of impacts, but at lower magnitude than SAG mill balls, due t o the smaller (PDF) A comparison of wear rates of ball mill

Grinding Ball Wear Breakage by Impact

18/10/2017 Although the true wear test of a grinding ball is its life in a real ball mill, the laboratory tests of impact and abrasion may serve as a guide to expected ball life The two most significant differences found among the 03/08/2018 Magnetoabrasive materials, obtained via the joint mechanical activation of magnetic (metal) and abrasive (diamond, silicon carbide) components in a highenergy planetarytype ball mill, are studied by means of XRD phase analysis and optical and scanningelectron microscopy It is shown that a metallomatrix structure forms in an Fe/diamond system after MagnetoAbrasive Materials SpringerLinkBall milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the Ball Milling Material Milling, Jet Milling AVEKA

abrasive materials wet ball millmining equiments supplier

abrasive materials wet ball millmining equiments supplier Vibration ball mill, also known as a vibrating ball mill or vibratory ball mill, is a kind of ball mill machine that uses the highfrequency vibration of the cylinder to make the grinding medium in the cylinder impact the material by inertial force Vibration ball mill is a new type of highefficiency and energysaving grinding Ball mills are commonly used for crushing and grinding the materials into an extremely fine form The ball mill contains a hollow cylindrical shell that rotates about its axis This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker View chapter Purchase Ball Mills an overview ScienceDirect Topics22/05/2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically fall and impact and grind the material in the cylinder to The working principle of ball mill Meetyou Carbide

Ball mill Schenck Process Holding GmbH horizontal

The Raymond® Ball Mill, also known as a tube mill, is designed for a wide variety of applications where hard, abrasive materials are ground to a required fineness Raymond® mills are used in many industries including mineral processing, cement plants, power generation and more Ball Mills are slow speed horizontal mills with a rugged design and ease of maintenance coupled 17/08/2021 C Ball mill is an open system, hence sterility is a question D Fibrous materials cannot be milled by ball mill 10 What particle size can be obtained through ball mill? A 20 to 80 mesh B 4 to 325 mesh C 20 to 200 mesh D 1 to 30 mm ANSWERS:1 Both B and C 2 Optimum speed 3 Longitudinal axis 4 Both 5 A – 3 B – 4 C – 2 D – 1 6 Ball Mill Principle, Construction, Uses, Advantage The raymond ball mill also known as a tube mill is designed for a wide variety of applications where hard abrasive materials are ground to a required fineness raymond mills are compare this product dont compare this product ball mill vertical for Ball MillBall Mill Abrasive Grinding Ball For Coal Mill

abrasive wet ball mill raymond leuchtfeuerwerkat

Raymond® Ball Mill Grinding hard or abrasive materials to a required fineness The Raymond® Ball Mill, also known as a tube mill, is designed for a wide variety of applications where hard, abrasive materials are ground to a required fineness Raymond® mills are used in many industries including mineral processing, cement plants, powergrinding mill wear materials grinding mill wear materials FL ball mill for cement grinding FL One, grinding mill wear materials,Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement The mill may operate in either open or closed circuit Abrasive Material Types Industrial grinding of abrasive materials in the millWhat is ball milling process answers Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process Ball mill is the most common grinding equipment in mining process, and widely applied Material Grinding Abrasive Ball mill critical speed mineral processing amp metallurgy a ball mill critical speed actually ball, rod, ag or sag is the ball mill processes abrasive