aluminum paste production process r

2023-04-16T07:04:12+00:00

Aluminium production process

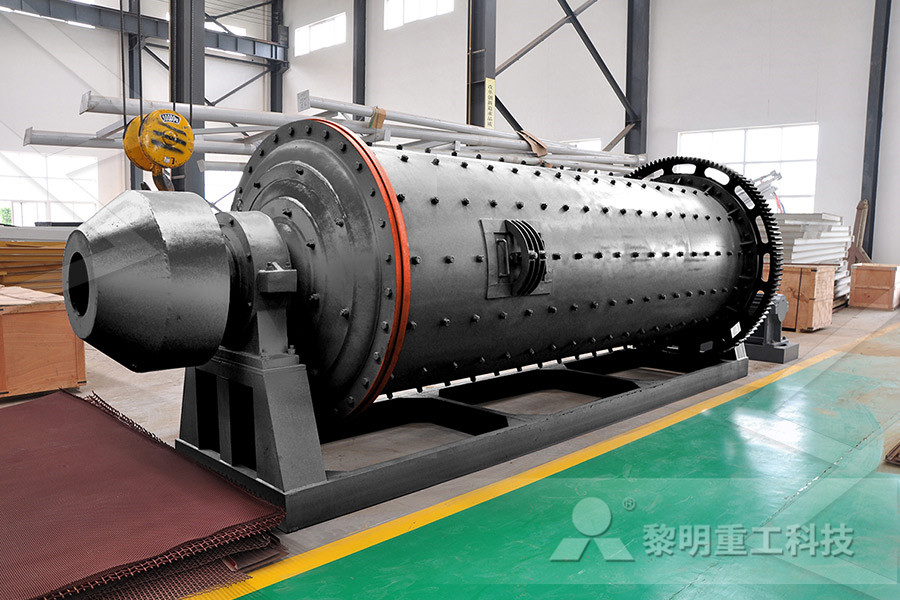

ALUMINIUM ALLOYS The process where the aluminium is shaped to its required form This process is used for making the vast majority of aluminium products from spectacle frames, telephone bodies, aeroplane fuselages or The ball mill puts the selected aluminum foil or aluminum particles and the aqueous solution of various additives with oil into the ball mill for grinding During the grinding process, the temperature in the machine should be strictly controlled If the temperature is too high, it can be adjusted by cooling with water Wait for the fineness of the material When the requirements China Aluminum powder paste production process Manufacture Aluminium paste generally consists of microscopic flakeshaped aluminium particles finely dispersed in an organicsolvent or aqueousbased carrierAsahi Kasei Aluminium Paste ( Aluminum Paste )

aluminum paste production process

aluminum paste production process Aluminium production process The aluminium production process starts with the mining of bauxites, an aluminium rich mineral in in the form of aluminium hydroxide About 90% of global bauxite supply is found in tropical areas Crushing ALUMINA PRODThe aluminium production process starts with the mining of bauxites, an aluminium rich mineral in in the form of aluminium hydroxide About 90% of global bauxite supply is found in tropical areas Crushing ALUMINA Aluminium production processLet me introduce the production process of aluminum powder paste When raw material quality control uses aluminum foil scraps as raw materials, the foil must be selected first, the oxidized foil is picked out, and the aluminum foils of different thicknesses are separated to ensure the uniform thickness of the raw materials When aluminum ingots are used as raw materials, it is China Aluminum powder paste production process Manufacture

Leafing Aluminium Paste Aluminum powder paste production

Leafing Aluminium Paste Aluminum powder paste production process – Tengan Detail: The use of aluminum powder paste has a certain status in the building materials industry Our product quality has a considerable number of users in the industry, and the product quality is guaranteed Let me introduce the production process of aluminum powder paste When Aluminium paste generally consists of microscopic flakeshaped aluminium particles finely dispersed in an organicsolvent or aqueousbased carrier HOME > Asahi Kasei Aluminium Paste Production processAsahi Kasei Aluminium Paste ( Aluminum Paste ) aluminum paste production process Aluminium production process The aluminium production process starts with the mining of bauxites, an aluminium rich mineral in in the form of aluminium hydroxide About 90% of global bauxite supply is found in tropical areas Crushing ALUMINA PRODaluminum paste production process

How aluminium is produced

The aluminium production process can be broken down into three stages; first bauxites, which contain aluminium, are extracted from the ground Second, bauxites are processed into alumina or aluminium oxide, and finally in stage Production and Processing of Aluminum 21 Extraction of Aluminum The extraction of aluminum from its ore and subsequent processing into finished products takes place in a series of successive operations, each largely independent of the other Generally the various processes are carried out at different plant sites A summary of production steps from the bauxite mine Chapter 2 Production and Processing of Aluminum121 Primary Aluminum Production 1211 General 1 Primary aluminum refers to aluminum produced directly from mined ore The ore is refined and electrolytically reduced to elemental aluminum There are 13 companies operating 23 primary aluminum reduction facilities in the U S In 1991, these facilities produced 45 million tons of primary aluminum 1212 Process 121 Primary Aluminum Production

The aluminium production process Comhan Aluminium

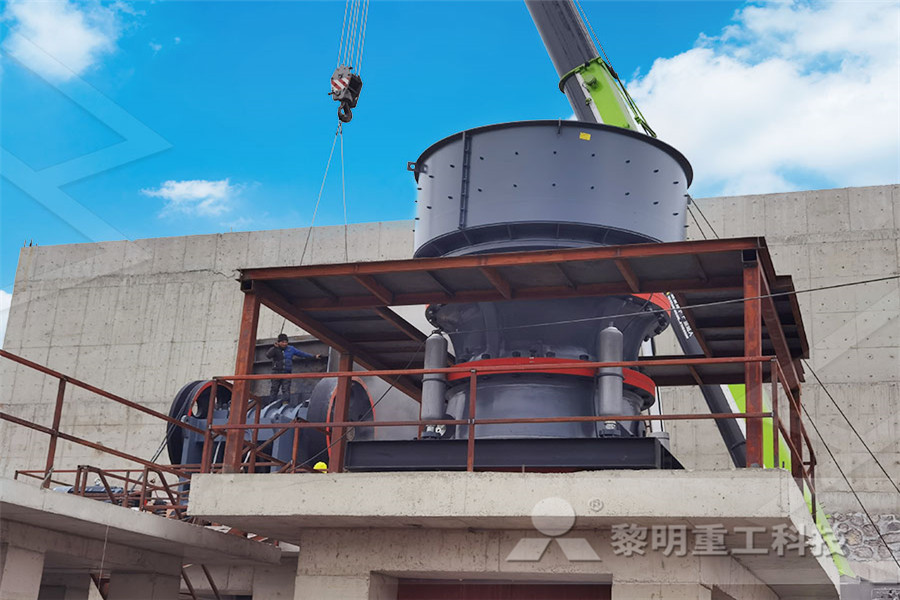

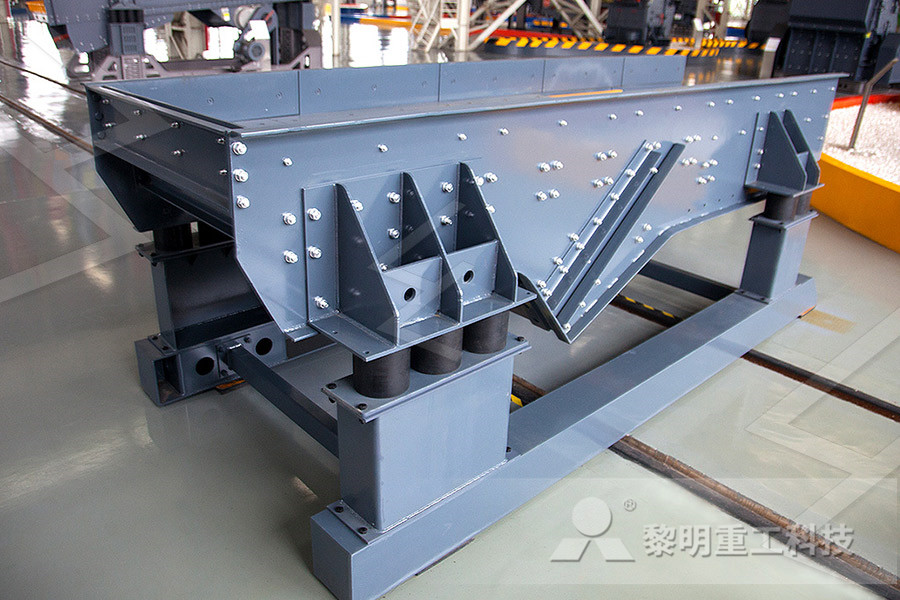

The complete production process from aluminium is a fascinating procedure Starting with the extraction of the bauxite, through to the conversion of alumina and ultimately to the entire electrolysis process The end product: pure aluminium, ready to be further processed by postprocessing companies Aluminium has many characteristic properties which make it a very Aluminum Powder 101 Production of aluminum powder Aluminum powder was originally produced by using a stamp mill to create flakes In the 1920s, E J Hall pioneered the process of spraying molten aluminum to make powder droplets Today, molten aluminum is sprayed under high pressure to produce a fine granular powder Two types of powder Processing 101 The Aluminum Associationaluminium paste production Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designs Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter read more Belt aluminium paste production asiacrusher

Aluminium Paste Ball Mill Process In Nigeria HN mining

Aluminium Paste Ball Mill Process In Nigeria News Introduction:The process starts by checking the alumina and other additives for correct chemical composition and subsequently storing them in different silos connecting to a continuous ball millAll the tank, silo and ball mill inputoutput are controlled by SKADA to eliminate the manual errors in the processbauxite aluminium ore mining operations process bauxite aluminium ore mining operations process Process Of Mining Bauxite Bauxite mining about two thirds of the bauxite mined in australia is used locally to produce alumina in 2019 approximately 43 mt of australia’s bauxite production was exported – valued at around 16 billion total production in 2019 was Aluminium Paste Ball Mill Process In NigeriaHN Mining Aluminium Paste SCHLENK has a complete range of aluminum paste, leafing and nonleafing grades, applicable for coatings, plastics and printing industries Technical Aluminium flakes are generally offered in a paste form for the production of light weight concreteAluminum Paste SCHLENK

DEB2 METHOD OF MANUFACTURING WATER

paste grinding water aluminum production Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Granted Application number DE Other languages German (de) Other versions DEA1 (en Process of Manufacture The aluminium powder is manufactured in several forms such as flakelike particles, granular powder (atomised aluminium) etc For the production of aluminium powder, there are several processes, one can use any of them The metal is melted in furnaces and the temperature maintained is around 720 O to 760 C Atomised Aluminium Powder DCMSMEand independently invented the aluminum production process in the same year, 1886, at the age of 23 years Completing the remarkab le coincidences, both died in (PDF) The Aluminum Smelting Process ResearchGate

aluminium paste for aac production line

type aluminium powder or paste used in aac powder, aluminium paste, aluminum powder, aluminum paste, aac plant, aac In AAC block production line,we will pour the slurry to aac block mould after Particle size (D50) 30 micron chemical foaming chemical foaming material aluminium paste for AAC concrete block making Product Description 125 Reduced temperature aluminum production process As mentioned above, the present day Bayer process of producing aluminum metal involves a temperature around 1000 °C But recently Argonne National Laboratory, USA improvised a reduced temperature aluminum production process which is currently undergoing pilot plant trialAluminum Smelter an overview ScienceDirect Topics31/07/2020 Manufacturing process of Aluminium powder Aluminum powder could be a fine granular powder made of Aluminium Aluminum powder is a Manufacturing process of Aluminium powder by Shivam