extraction of iron from haematite r

2021-02-24T00:02:45+00:00

Extraction of Iron from Haematite KDRChemistry

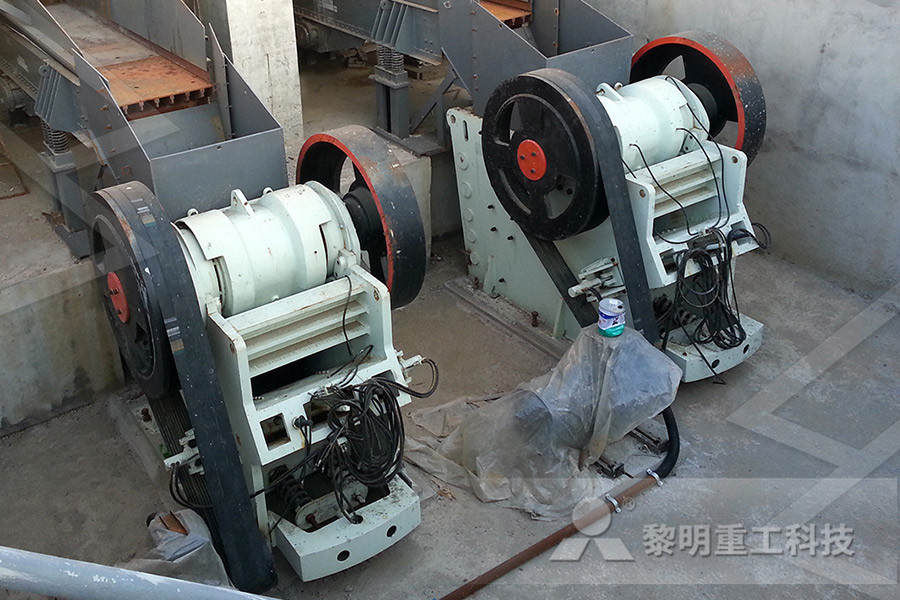

Extraction of Iron from Haematite Step 1: The Iron ore is crushed and broken into smaller pieces, concentrated with gravity separation process (washed with water) Step 2: The raw materials are added into the top of the furnace : Iron ore (Haematite, Fe2O3), Coke (Carbon, C), Limestone (CaCO3) Step 3: It is heated by blowing hot air at the Extraction of iron is based on the reduction of HAEMATITE (Fe 2 O 3) with carbon The process of the extraction of iron is carried out by the following steps: In this metallurgical operation, the ore is concentrated by removing impurities like soil EXTRACTION OF IRON EXTRACTION OF IRON FROM HAEMATITEExtraction of Iron from Haematite Extraction of Iron: Iron is extracted from its chief ore Haematite Fe 2 O 3The various steps involved in the process are as follows: 1 Crushing: The ores are crushed in jaw crusher and powdered in ball mills 2 Concentration: The crushed ore is washed with steam or cold water to remove clay and sand The washed ore is then extraction iron from haematite servicetechniquefr

Extracting iron Iron and aluminium GCSE Chemistry

Iron ores such as haematite contain iron(III) oxide, Fe 2 O 3 The oxygen must be removed from the iron(III) oxide in order to leave the iron behind Solution Iron is extracted from its ore, haematite in a blast furnace The ore is led into the top of the furnace along with coke and limestone The limestone decomposes in the hot furnace, forming calcium oxide This reacts with the sandy impurities (silicon dioxide) to form a slagHow is iron extracted from haematite? topprExtraction of Metals Extraction of Iron Iron is extracted from its ore in the blast furnace The main iron ore is called haematite Haematite is iron(III) oxide Fe 2 O 3 The iron ore contains impurities, mainly silica (silicon dioxide) Limestone (calcium carbonate) is added to the iron ore which reacts with the silica to form molten calcium silicate in the blast furnaceGCSE CHEMISTRY Extraction of Iron Haematite

Extraction of Iron Class 12, General Principles and

15/05/2020 Extraction of Iron The cast iron is usually extracted from its oxide ore (haematite) This process involves the following steps: 1) Concentration The ore is crushed in jaw crushers and is broken to small pieces of about 1 inch in size The crushed ore is concentrated by gravity separation process in which it is washed with water to remove clay, sand, etc 2) Calcination About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Extraction of Iron from haematite YouTubeExtraction of Metals Extraction of Iron Iron is extracted from its ore in the blast furnace The main iron ore is called haematite Haematite is iron(III) oxide Fe 2 O 3 The iron ore contains impurities, mainly silica (silicon dioxide) Limestone (calcium carbonate) is added to the iron ore which reacts with the silica to form molten calcium silicate in the blast furnaceGCSE CHEMISTRY Extraction of Iron Haematite

the essential reactions in the extraction of iron from

Iron Extraction Process Separation Of Hematite hematite, also spelled as haematite, is a common iron oxide with the formula fe2o3 and is widespread in rocks and soils hematite crystallizes in the rhombohedral lattice system, and it has the same crystal structure as ilmenite and corundumematite and ilmenite form a complete solid solution at temperatures Iron ores such as haematite contain iron(III) oxide, Fe 2 O 3 The oxygen must be removed from the iron(III) oxide in order to leave the iron behind Extracting iron Redox, extraction of iron and transition EXTRACTION OF IRON INTRODUCTION Iron is extracted from its ore called HAEMATITE (Fe2O3) oxide PRINCIPLE OF EXTRACTION Extraction of iron is based on the reduction of HAEMATITE (Fe2O3) with carbon DETAILS OF EXTRACTION The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of (PDF) EXTRACTION OF IRON Fahad Zafar Academiaedu

Extraction of Iron Class 12, General Principles and

15/05/2020 Extraction of Iron The cast iron is usually extracted from its oxide ore (haematite) This process involves the following steps: 1) Concentration The ore is crushed in jaw crushers and is broken to small pieces of about 1 inch in size The crushed ore is concentrated by gravity separation process in which it is washed with water to remove clay, sand, etc 2) Calcination 27/09/2021 Malleable Iron is the purest form of iron available commercially and is prepared from cast iron by heating cast iron in a furnace lined with Haematite (Fe2O3) The Haematite then reacts with Carbon in the cast iron to give pure iron and carbon monoxide gas Fe 2 O 3 +3C→2Fe+3CO Limestone then creates the slagExtraction of Iron: Meaning, Purification, Extraction 19/12/2021 38 Extraction of Iron from Haematite; What Commonly Used Metal Is Extracted From Hematite? Iron What metal is extracted from hematite? Iron Iron is extracted from iron ore in a huge container called a blast furnace Iron ores such as haematite contain iron(III) oxide, Fe 2 O 3 The oxygen must be removed from the iron(III) oxide in order to leave the iron what commonly used metal is extracted from hematite

Extraction of Metals (1021) CIE IGCSE Chemistry

The extraction of iron in the blast furnace Diagram showing the carbon extraction of iron Raw Materials: Iron Ore (Haematite), Coke, Limestone and AirExplanation: Iron Ore, Coke and Limestone are mixed together and fed into the top of the blast furnace Hot air is blasted into the bottom of the blast furnace ; Zone 1 Coke is used as the starting material It is an impure Click here👆to get an answer to your question ️ In the preparation of iron from haematite (Fe2O3) by the reaction with carbon as given below: Fe2O3 + C → Fe + CO2 How much 80 % pure iron could be produced from 120 kg of 90 % pure Fe2O3 ?In the preparation of iron from haematite (Fe2O3) by the Extraction of Iron from Haematite Grade 12 Science Notes In this zone Fe 2 O 3 is reduced to iron by co in three steps 3Fe 2 O 3 + CO → 2Fe 3 O 4 + 2 Fe 3 O 4 + CO → 3FeO + 2 FeO + CO → Fe + CO 2 Solid state From the bottom of blast furnace, molten slag and molten iron are tapped out Details > Hematite , also spelled as haematite, is a common oxide with a Extraction of Iron from Haematite Screwer

GCSE CHEMISTRY Extraction of Iron Haematite

Extraction of Metals Extraction of Iron Iron is extracted from its ore in the blast furnace The main iron ore is called haematite Haematite is iron(III) oxide Fe 2 O 3 The iron ore contains impurities, mainly silica (silicon dioxide) Limestone (calcium carbonate) is added to the iron ore which reacts with the silica to form molten calcium silicate in the blast furnaceExtraction of Iron from HaematiteThe inhibitor of uses the sodium silicate, tannin and sodium lignosulfonate, and their inhibitory effect is the best when the pH value is 89 In terms of the properties of haematite , the reverse method is more advantageous as the method used for the of from haematite than the positive method Leave Us Now Relate Product What Can I Do For Extraction of Iron from Haematite Phactorize19/04/2001 Iron is extracted from haematite, Fe 2 O 3 by reduction in a blast furnace The raw materials Iron ore this contains the iron Coke this is almost pure carbon This is to reduce the iron oxide to iron metal by removing the oxygen Limestone this takes away impurities in the form of slag Step 1 Reducing the iron ore to iron Hot air is blasted into the furnace, raising Extracting Iron from haematite Everything2

extraction of iron from haematite ore

Extraction of Iron from Haematite Xinhai Extraction of iron from haematite: Magnetic separation method Haematite magnetic separation method mostly adopts a weakstrong magnetic separation method, which is used for the extraction of iron from haematitemagnetite mixed ore Tailings of lowintensity magnetic separation are sent to Iron, when extracted from iron ore such as haematite containing iron(III) oxide, Fe 2 O 3, in a blast furnace is called iron extraction blast furnace metallurgy In this reduction reaction, oxygen is removed from the iron(III) oxide to leave behind iron Generally, the extraction of metals and their isolation are based on three major procedures The steps are:Iron Extraction by Blast Furnace Metallurgy Procedure 27/09/2021 Malleable Iron is the purest form of iron available commercially and is prepared from cast iron by heating cast iron in a furnace lined with Haematite (Fe2O3) The Haematite then reacts with Carbon in the cast iron to give pure iron and carbon monoxide gas Fe 2 O 3 +3C→2Fe+3CO Limestone then creates the slagExtraction of Iron: Meaning, Purification, Extraction

what commonly used metal is extracted from hematite

19/12/2021 38 Extraction of Iron from Haematite; What Commonly Used Metal Is Extracted From Hematite? Iron What metal is extracted from hematite? Iron Iron is extracted from iron ore in a huge container called a blast furnace Iron ores such as haematite contain iron(III) oxide, Fe 2 O 3 The oxygen must be removed from the iron(III) oxide in order to leave the iron 14/05/2019 Assertion : For the extraction of iron, haematite ore is used Reason : Haematite is a carbonate ore fo iron (1) Both the assertion and reson are correct, but the reason is not hte correct explanation for the assertion (2) Both the assertion and reason are correct and the reason is the correct explanation for the assertionAssertion : For the extraction of iron, haematite ore is How would you best extract iron from haematite (iron ore)? answer choices reduction by carbon electrolysis decomposition oxidation Tags: Question 8 SURVEY 60 seconds Q Which reaction is used to keep the furnace hot? answer choices CO 2 + C > 2CO C + O 2 > CO 2 Fe 2 O 3 + 3C > 2Fe + 3CO C + O 2 > CO 2 Tags: Question 9 SURVEY 60 Extraction of metals Metals Quiz Quizizz