iron ore ncentration floatation process r

2021-08-24T07:08:44+00:00

iron ore concentration floatation process

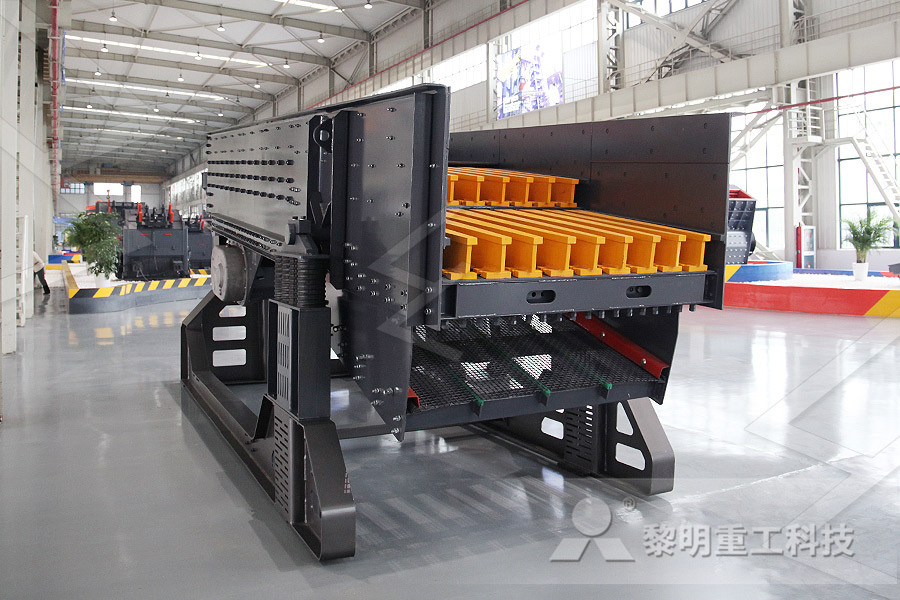

Iron Ore Concentration Process Magnetite is mined in large chunks and is crushed into small particles by a series of crushers After primary crushing with jaw crushers and secondary crushing with gyratory crushers and tertiary crushing with cone or high pressure grinding rolls (HPGR), the ore is screened on vibrating screens to size the particlesIron Ore Concentration Floatation Process Aug 05, 2010 A novel twostep flotation process was developed for the separation of iron concentrate from Donganshan carbonaceous iron ore through which the siderite concentrate is first recovered and the high quality hematite concentrates with relative high iron recovery can be obtained in the second step flotationIron Ore Concentration Floatation ProcessHN Mining Iron Ore Concentration Process With Grinding Circuit, Dry Desliming And Dry Or Mixed (Dry And Wet) Concentration the present invention discloses an advantageous and effective process for the concentration of iron ores, which can be fully dry or mixed, part of the process being dry, part wet, such enhancing the process efficiency as a whole by increasing recovery Concentration Of Iron Ore By Flottation

Iron Ore Concentration Process Flotation

Iron Ore Concentration Process Flotation July 27, 2021 Production of High Grade Iron Ore Concentrates Using The flotation rate constant for the silica particles is affected by feed grade and particle size Many iron ore concentrators use the quantity of 15 mm 100 mesh material in the flotation feed as a measure of the performance of the grinding circuit This particle size is Iron Ore Concentration Process With Grinding Circuit Dry 5 IRON ORE CONCENTRATION PROCESS WITH DRY GRINDING CIRCUIT, DRY DESLIMING AND DRY CONCENTRATION, according to the claims 1 to 4, wherein the said process is applied for concentration of iron ores with alternatively two stages of grinding and regrinding, usually used for ores with fine Iron Ore Concentration Floatation ProcessIron Ore Concentration Floatation Process News Introduction: [ protected] Send Message Get a Quote Contact Us [ protected] Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China Get Latest Price Get in Touch If you have any problems about our product and service,please feel free to give your inquiry in the form below Iron Ore Concentration Floatation Process HN droled mine

iron ore ncentration floatation process fbmmenuiseriefr

Iron Ore Concentration Process Flotation Whatever your requirements, you 'll find the perfect servoriented solution to match your specific needs with our helpWe are here for your questions anytime 24/7, welcome Get Prices iron ore floatation process betramos Process Introduction There are a lot of iron ore in nature which containes highly quantities of hematite The flotation method of concentration, used extensively for other metal ores, has only recently been utilized for hematite iron ores It can be applied as either the sole concentration process or as a final concentration stage to ensure a highgrade product In the flotation process, air is bubbled through a suspension of fine iron ore in waterCHAPTER9 FROTH FLOTATION AND ITS APPLICATION TO 11/01/2016 What Ore is Suitable for Flotation The largest class of ores treated by the flotation process consists of those containing the sulphide minerals of copper ; these sometimes contain native copper and also gold and silver, all of which can generally be floated with the sulphide minerals in one concentrate Any pyrite or other iron sulphide present can usually be Flotation Mineral Processing Metallurgy

Iron Ore Concentration Multotec

Iron Ore Concentration Iron Ore Concentration Iron ore concentration is a mineralspecific concentration process within the mineral processing industry Multotec has customdeveloped mineral processing concentration equipment to suit all Iron Ore Concentration Process Flotation Iron Ore processed with high heat and carbon to produce a stronger, more flexible metal This item can be manufactured in the CentriForge from Iron Ore and either Light Basalt or Dark Basalt at Processing Power 1Iron Ore Concentration Process FlotationIn the iron ore flotation process, mineral particle size, pulp concentration, flotation reagent system, and other factors will be the elements to influence the iron ore flotation results The iron ore particle size can largely affect the crushing and grinding stage, which is mainly to dissipate for useful mineral ore monome and provide Iron Ore Concentration Floatation Process

Iron Ore Concentration Floatation Process HN droled mine

Iron Ore Concentration Floatation Process News Introduction: [ protected] Send Message Get a Quote Contact Us [ protected] Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China Get Latest Price Get in Touch If you have any problems about our product and service,please feel free to give your inquiry in the form below 02/01/2012 With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove Froth Flotation of Iron Ores01/01/2006 Divrig ˘ i Iron Ore Concentrator was designed to process 670 t = h magnetite ore containing 53–55 % Fe and to produce 310 t = h of coarse concentrate assaying 63–65 % (PDF) Flotation of iron ore processing plant tailings

CHAPTER9 FROTH FLOTATION AND ITS APPLICATION TO

concentration process or as a final concentration stage to ensure a highgrade product In the flotation process, air is bubbled through a suspension of fine iron ore in water to which a small quantity of flotation reagent is added This reagent modifies the surface of either the iron oxide or the principal gangue component, normally silica, so that these particles attach themselves iron ore concentration process flotation Flotation MachineIron Ore Flotation Cell And Consentration We have iron ore concentration flotation in chinairon ore concentration plant in china iron processing iron processing use of a smelting process to turn the ore into a form from which products can be fashioned included in this article also is a discussion of the mining iron ore concentration floatation processThe flotation process depends on several design First, the collector is added to the iron ore slurry to selectively coat the iron oxide particles, making the surface hydrophobic The slurry then goes to a flotation cell, where air bubbles are generated using an impeller and aerator (Figure 124) At this step, the frother (for example, fuel oil) is added to the ore slurry to form stable Flotation Process an overview ScienceDirect Topics

iron ore concentrate flotation process Solution for ore

Iron ore concentration plants and Main Process Equipment Caiman Type of process: Iron Ore Concentrator with magnetic separation and froth flotation Primary Feed rate: 1176 MTPH Concentrate production: Iron ore concentrate 5,1 million t/year Iron ore mining process and iron ore mining equipments Iron Ore Concentration Process Flotation July 27, 2021 Production of High Grade Iron Ore Concentrates Using The flotation rate constant for the silica particles is affected by feed grade and particle size Many iron ore concentrators use the quantity of 15 mm 100 mesh material in the flotation feed as a measure of the performance of the grinding circuit This particle size is Iron Ore Concentration Process FlotationFlotation of Iron Ore: A Brief Review Guixia Fan 1, Liguang Wang 2, Yijun Cao 1 and Chao Li 3,* 1 School of Chemical Engineering, Zhengzhou University, Zhengzhou , China; cumtfgx@126 (GF); yijuncao@126 (YC) 2 School of Chemical Engineering, The University of Queensland, Brisbane, Queensland 4072, Australia; 3 Flotation of Iron Ore: A Brief Review

(PDF) Flotation of Iron Ores: A Review

19/11/2019 A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into Iron Ore Concentration Floatation Process Rock Star Mobile Crushers Hematite iron ore process plant Stone Crushing Production Crusher used for aggregated rock producing divides to primary crushing secondary crushing and stone sharping processing Flotation Production Line Lots of mineral ores beneficiation can use this method the separation process mainly used by Iron Ore Concentration Floatation Process Rock Star Mobile Iron ore flotation is now well established commercially around the globe, where large tonnages are treated to provide economically viable upgrading for a variety of oxide ore types In this (PDF) Reagents in iron ores flotation

Flotation Mineral Processing Metallurgy

11/01/2016 What Ore is Suitable for Flotation The largest class of ores treated by the flotation process consists of those containing the sulphide minerals of copper ; these sometimes contain native copper and also gold and silver, all of which can generally be floated with the sulphide minerals in one concentrate Any pyrite or other iron sulphide present can usually be Concentration of Ores: Hydraulic Washing, Froth Flotation This method is based on the differences in weight between the gangue and the metal Generally, the Home; Products; Cases; About Us; Contact Us; flotation concentration iron ore T20:05:00+00:00 Mobile Crushers; Stationary Crushers; Grinding Mill; Washing Screening; Ore Beneficiation; flotation concentration iron ore jacquesmarmetfrThe mass and iron metallurgical recoveries reached, respectively, 417% and 805% in the flotation stage, and 179% and 334% in the global desliming and flotation process The high process selectivity yielded tailings assaying 12% iron in a single rougher stage The controlled use of wash water was essential for the removal from the froth of entrained fine iron minerals Improving recovery of iron using column flotation of iron

Beneficiation of Iron Ore Mineral Processing Metallurgy

24/05/2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring