dynamics of crushing in a vsi

2023-08-05T14:08:24+00:00

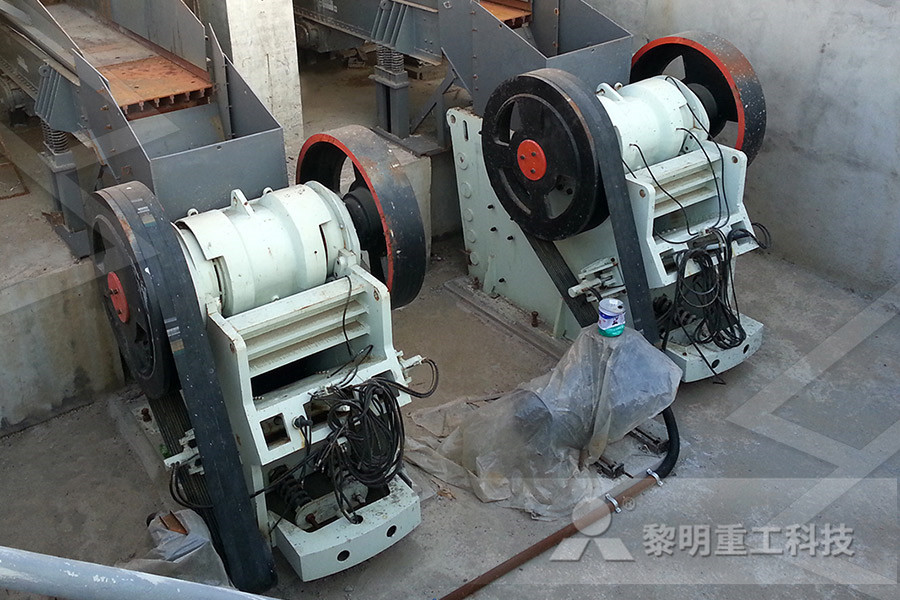

Study of Kinematic and Dynamic Analysis of Jaw Crusher

crushers, the VSI (Vertical Shaft Impactor) use a special approach involving a high speed rotor with wear resistant tips and a crushing chamber designed to 'throw' the rock against The VSI crushers utilize speed instead of surface force as the predominant force to break rock In its state of nature, rock features a jagged and uneven surface Using FLUENT software, a coupling model of computational fluid dynamics (CFD) and the discrete phase model (DPM) is used to simulate the airflow distribution and particle traces in a Mathematical modeling of a vertical shaft impact crusher The dynamics of the particles has been shown to determine the product size distribution A detailed description of the dynamics of the particles inside and exiting a rotor was provided by Rychel [6] However, Kojovic [7] formulated a predictive model for the VSI crusher that correlated product size with power draw based on breakage of the ore in aFitforPurpose VSI Modelling Framework for Process

Optimal energy control of a crushing process based on

1 Introduction Vertical shaft impact (VSI) crushers are processing machines which are usually used in tertiary crushing stations of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape and large amount of fines is required , When compared to other tertiary crushers such as cone crushers, VSI The use of vertical shaft impact (VSI) crushers is one possible solution, since VSI crushers can create particles with a good aspect ratio and smooth surfaces for use in different applications Simulation of particle flows and breakage in crushers The modelled VSI is based on measurements from a Barmac 5100SE VSI crusher taken from a mobile crushing plant located in a quarry in Gävle at the time Eight different rotor designs were created in a systematic way using a Design of Experiments approach Each individual rotor was then placed inside a VSI and a DEMModeling and Optimization of a Vertical Shaft

Simulation and experimental study on the stone powder

In the VSI crushing process, the diffusion of a large amount of produced stone powder (with particle diameters below 0075 mm) seriously pollutes the environment Additionally, too much stone powder content in the finished product affects the quality of the manufactured sand Unlike other types of impact crushers, vertical shaft impact crushers (VSI) are designed with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shapeCRUSHING SCREENING Crushing and ScreeningVertical shaft impact (VSI) crushers are usually used in tertiary crushing station of both aggregate and mining industries for crushing of hard rock material or ores when a product material with Energy considerations in compressive and impact crushing

Theory Of Hydrocone Crusher Crusher Mills, Cone

84in Hydrocone crusher lor tertiary crushing 01 SemiTaconite are (specular hematite) Cone Crushers – Document Summary – mining research library For example, a Model 1084 Hydrocone crusher has an 84in diam man¬tle, and is capable of accepting a 10in diam sphere at the feed point to the crushing chamber Using FLUENT software, a coupling model of computational fluid dynamics (CFD) and the discrete phase model (DPM) is used to simulate the airflow distribution and particle traces in a Mathematical modeling of a vertical shaft impact crusher The dynamics of the particles has been shown to determine the product size distribution A detailed description of the dynamics of the particles inside and exiting a rotor was provided by Rychel [6] However, Kojovic [7] formulated a predictive model for the VSI crusher that correlated product size with power draw based on breakage of the ore in aFitforPurpose VSI Modelling Framework for Process

The Difference Between Two Crushing Methods Of VSI

The Difference Between Two Crushing Methods Of VSI Crusher In mechanical sand production industries, vertical shaft impactors are widely used as sand making equipment The VSI crusher has two feeding methods: complete center feeding and center feeding accompanied by waterfall feeding The way is also: “rock on rock” and “rock on steel”VSI and GS series crushers feature a unique combination of rotor design, wear material, and crushing equipment design This combination is proven to be a revolutionary in improving capacity and superior product shape quality and in reducing operating and wear costsVertical Shaft Impact Crusher AF AF Minerals CEMCO now supplies VSI crushing equipment in 26 nations to the majority of the world's largest producers and most "green friendly" companies Crusher – Wikipedia, the free encyclopedia with less steepness in the crushing chamber and more of a parallel zone between crushing zonesVsi Crusher Hitachi Rock Crushers Crusher Mills, Cone

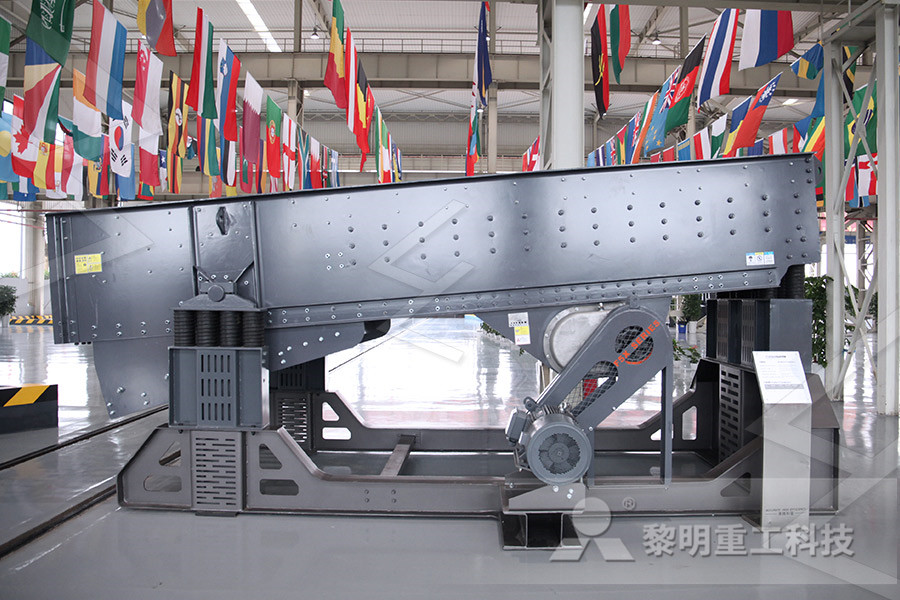

CRUSHING SCREENING Crushing and Screening

Unlike other types of impact crushers, vertical shaft impact crushers (VSI) are designed with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape The modelled VSI is based on measurements from a Barmac 5100SE VSI crusher taken from a mobile crushing plant located in a quarry in Gävle at the time Eight different rotor designs were created in a systematic way using a Design of Experiments approach Each individual rotor was then placed inside a VSI and a DEMModeling and Optimization of a Vertical Shaft Steadystate modelling and simulation tools are widely used in designing of a new process for industrial coarse comminution circuit (crushing plant) (NapierMunn et al 1996;King 2001)(PDF) Crushing Plant Dynamics ResearchGate

Jaw Crusher VS Impact Crusher (A Comparison

1 Application 1 Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt 2 Impact crusher is usually used as a mediumfine hardness crusher, such as limestone, concrete, it has A vertical shaft impactor (VSI) type crusher can also be used as a precrushing unit in cement grinding circuits to carry out an efficient grinding process This type of application will reduce the total grinding energy requirement by increasing Effect of precrushing with a vertical shaft separation size has increased the production of the 1632 mm fraction in the VSI crusher Figure 7 Capacities for the 02 mm, 25 mm, 58 mm, 8 11 mm, 1116 mm and 1632 mm fractions with a (PDF) Size and shape simulation in a tertiary

NSSGA AGG1 webinar to cover VSI crushing : Pit Quarry

The National Stone, Sand Gravel Association (NSSGA) plans to host its AGG1 webinar, “Tuning and Operations of VSI Crushing,” at 1 pm EST on June 23 Neil Hise, president of CEMCO Inc, will present the webinarHe has 45 years of experience with the operation and service of vertical shaft impact (VSI) crushers, NSSGA reports According to crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer Assortment of a proper crushing chamber for the material Feed rate controlDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT Barmac® B7150SE™ VSI crusher is ideal for the last crushing stage to process rocks, recycled materials, ores, and minerals For stationary, portable and mobile crushing applications Menu Close Industries Mining Supporting your mining operations, from plant design expertise to equipment, parts and services for every stage of your process Barmac® B7150SE™ impact crusher

Barmac® B9100SE™ impact crusher

Barmac® B9100SE™ VSI crusher is the largest model in Barmac® B Series™ family it is available as a stationary, portable or mobile crushing unit Excellent third or fourth stage reduction unit, Barmac® B9100SE™ has proven to be efficient in many demanding crushing operations in construction, industrial minerals, metallic minerals and waste recycling applicationsBarmac Vsi Crushers Barmac B Series Vsi 0 Weight t 78 assembly on bearing housing vsi crusher magnesium cone rock crusher crusher manufacture in china tugas site vsi crusher for sale Barmac VSI Crushers is the efficient VSI crusherBarmac vsi crusher spare parts with high were resistant ability can be process by , with drawing Assembly On Bearing Housing Barmac Vsi Crusher84in Hydrocone crusher lor tertiary crushing 01 SemiTaconite are (specular hematite) Cone Crushers – Document Summary – mining research library For example, a Model 1084 Hydrocone crusher has an 84in diam man¬tle, and is capable of accepting a 10in diam sphere at the feed point to the crushing chamberTheory Of Hydrocone Crusher Crusher Mills, Cone

Jaw Crusher VS Impact Crusher (A Comparison

1 Application 1 Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt 2 Impact crusher is usually used as a mediumfine hardness crusher, such as limestone, concrete, it has Crushing and Screening Handbook f MINERALS Minerals in brief Whether you need a single crusher, a multi stage process or a complete plant, we assist you To be successful in today’s quarry and sand and with the right (PDF) Crushing and Screening Handbook