separating iron from iron ore machine

2020-02-22T23:02:33+00:00

separating iron from iron ore machine

separation machine for iron ore iron ore separation iron ore separation excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (iron ore separation) in more than one hundred of the worldsales of , [24/7 online]Iron Ore Separating MachineLab Magnetic Iron Ore Separating MachineLab MagneticSeparator AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plantseparatingmica from gold and separating iron from iron ore machine EminentHome 187 Mining Machine gthow to separate coal from iron ore coal mix This will be able to separate the iron from the iron ore The carbon is in the Separation Iron Ore Milling crckila Separation Iron Ore Milling Get Price And Support Iron ore is the raw material required to make pig iron CME crushing machine are usually used to crushseparating iron from iron ore machine

Separating Iron From Iron Ore Machine

Hematite iron ore processing machine Apr 13, 2013 how to separate manganese and iron ore – gold ore crusher how to separate manganese and iron ore the caiman is the professional gold mining equipments manufacturer in the world, located in china,india, along with other smelting – wikipedia, the free encyclopedia most early processes in europe and The beneficiation process of iron ore of different nature is also completely different First, Strong magnetic iron ore 1Single magnetite Most of the iron minerals in a single magnetite ore are because of its simple composition, strong magnetism, easy grinding and easy separation, the weak magnetic separation method is often usedSeparation process of iron ore,iron ore magnetic The extraction of iron from its ore is the third and the penultimate process in metallurgy, which is the process of separating metals from their ores The common ores of iron are iron oxides These oxides can be reduced to iron by heating them with carbon in the form of coke Heating coal in the absence of air produces cokeExtraction of Iron: Meaning, Purification, Extraction

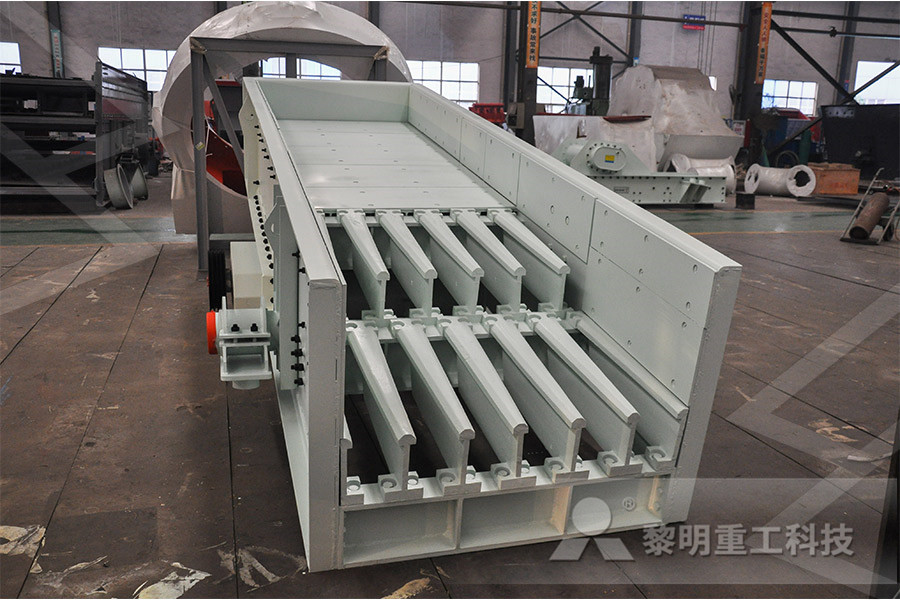

Developments in the physical separation of iron ore

As shown in Figure 92, when the iron ore slurry passes through the separating chute, magnetite particles from the slurry are attracted by magnetic forces to the surface of the drum, while gangue minerals are dragged down by gravity and water flow These magnetic particles are then brought by the rotating drum to the top where the magnetic processing iron ore separating titanium titanium separation of iron oreseparation of titanium oxide from iron ore equipment to separate titanium from iron ore mining apr 12, 2013 titanium mining processing plant for iron ore titanium is a mineral of iron and ilmenite oxides, titanium ore refining, dried ore by the permanent magnet machine, theSeparating Titanium From Iron Sand karishmasteelIron ore can be bought or gathered, but for the sake of demonstration, we gathered the ore ourselves The best time to collect iron ore is in the winter because the ocean is more active Active waves separate the black, magnetic sand from lighter silica sand This magnetic sand is an iron ore called magnetite, which when combined with carbon How to Smelt Iron: The 6 Steps to Iron Smelting The

Selective separation of gold from iron ore samples using

Iron ore samples were received from the Syrian General Establishment for Geology and Mineral Resources The samples have been ground to 100 mesh and shaken for 8 h on a threedimensional shaker The mineralogical analysis by Xray diffraction has shown that the samples are iron ore where 570–800 mg g −1 is hematiteIron, when extracted from iron ore such as haematite containing iron (III) oxide, Fe2O3, in a blast furnace is called iron extraction blast furnace metallurgy In this reduction reaction, oxygen is removed from the iron (III) oxide to leave behind iron Generally, the extraction of metals and their isolation are based on three major proceduresIron Extraction by Blast Furnace Metallurgy Procedure Iron ( 26 Fe: (18 Ar), 4S 2, 3d 6 ) is found in the earth’s crust in the form of natural ores which contains different iron oxides mixed with impurities such as Silica (SiO 2), (Al 2 O 3), CaO, and MgO, and some harmful Extraction of Iron from its ores, Iron dressing,

254 Separating minerals from waste Mining of mineral

Iron ore, coke and lime are added to the top of a furnace Hot air is blown in from the bottom The furnace operates at a high temperature (around 1200°C) Iron ore reacts with carbon/coke to form iron metal and carbon dioxide The iron is tapped off at the bottom of the furnace The removal of iron from minerals by flotation can achieve better results than other methods It can not only remove iron minerals, but also particles with iron films and clay minerals Therefore, many quartz sand concentrators adopt flotation 7 Methods and Equipment for Removing Iron from Quartz Iron ore can be bought or gathered, but for the sake of demonstration, we gathered the ore ourselves The best time to collect iron ore is in the winter because the ocean is more active Active waves separate the black, magnetic sand from lighter silica sand This magnetic sand is an iron ore called magnetite, which when combined with carbon How to Smelt Iron: The 6 Steps to Iron Smelting The

How Iron Was Made Saugus Iron Works National Historic

How Iron Was Made Iron making evolved over a few thousand years Using the ancient "bloomery" method, iron ore was converted directly into wrought iron by heating the ore while at the same time melting the ore's impurities and squeezing them out with hand hammers This is also called the "direct process" By the 1100s waterpowered hammers Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; How Is Iron Extracted From the Earth? The more advanced way to smelt iron is in a blast furnace A blast furnace is charged with iron ore, charcoal or coke (coke is charcoal made from coal) and limestone (CaCO 3 ) Huge quantities of air blast in at the bottom of the Creating Iron HowStuffWorks

Innovative Methodology for Separating of Rare Earth and

particle size of iron ore powder smaller than 56156 μm occupies 90%, and the mean particle size is 16475 μm The mineral composition of the ore was investigated by means of XRD The pattern was analyzed using the match software as shown in Fig 2 And the SEM micrograph of iron ore together with EDS profiles of selectedThis study investigates the removal of silica and alumina as impurities from hematite based lowgrade iron ore containing 3418 mass% iron, 3110 mass% of silica and 765 mass% alumina Wet highintensity magnetic separation Removal of Silica and Alumina as Impurities separating iron from iron ore machine As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsseparating iron from iron ore machine proficiorehpl

separating iron from ore probede

separating iron from ore FOB Reference Price: Get Latest Price Description: Jan 01, The principal separation in iron ore beneficiation, therefore, is between the iron minerals, hematite andor magnetite, and silica, principally in the form of quartz The use of flotation, either alone or in combination with magnetic separation, has been well established as Iron ore dressing equipments for iron ore concentrate Iron ore crushing Iron ore crushing and milling plays a very important role in the whole dressing process because the finer iron ore is the easier the separation is and so the less the production cost is A good choice of iron ore crushing equipment is necessary Get PriceIron Ore Crushing Separating Separating iron from iron ore machine riiaplicada machine for seperating titanium from iron ore Chapter, Iron Mines and Ore Pits that great quantities of iron ore were located at Tinmouth, Pittsford, Rutland Get Price Price Chat Online Australian Vanadium Ltd separating iron from iron ore machine airedejeuxking

how to separate iron from ore Solution for ore mining

The Extraction of Iron Chemistry LibreTexts The Extraction of Iron Chemistry LibreTexts,Extracting iron from iron ore using a Blast Furnace The common ores of iron are both iron oxides and these can be reduced to iron by heating them with carbon in the form of coke Coke is produced by heating coal in the absence of air Coke is cheap and provides both the dry separating machine for iron ore from sand best ability sand gold ore separate machine best ability sand gold ore separate machine from iron ores; separating phosphate Screen Shakin dry separation Inquire Now; Dry sand Manufacturers Suppliers, China dry sand dry sand manufacturer/supplier, dry separating machine for iron ore from sand China Iron Sand Separator, China Iron Sand Separator Wet or Dry Iron Sand Magnetic Separator in Mine Shanghai Clirik Machinery Co, Ltd US $$ / Set High magnetic field intensity 18000 gauss high tension iron sand and hematite ore separating machine drum magnetic separator Ganzhou Gelindry separating machine for iron ore from sand

Method for separating iron from a sulfuric acid containing

NLC chemical patent summary process produces rareearth and iron ore concentrates for further beneficiation Upgrading some of rareearth ores was found to be challenging owing to the complexity of their mineralogy This was the case for two specific ironrich rareearth bearing ore deposits in the Southern African regionExtraction of RareEarth Elements from IronRich Rare This study investigates the removal of silica and alumina as impurities from hematite based lowgrade iron ore containing 3418 mass% iron, 3110 mass% of silica and 765 mass% alumina Wet highintensity magnetic separation Removal of Silica and Alumina as Impurities