design nsultant for single toggle jaw crusher

2020-03-24T02:03:38+00:00

Design Consultant For Single Toggle Jaw Crusher

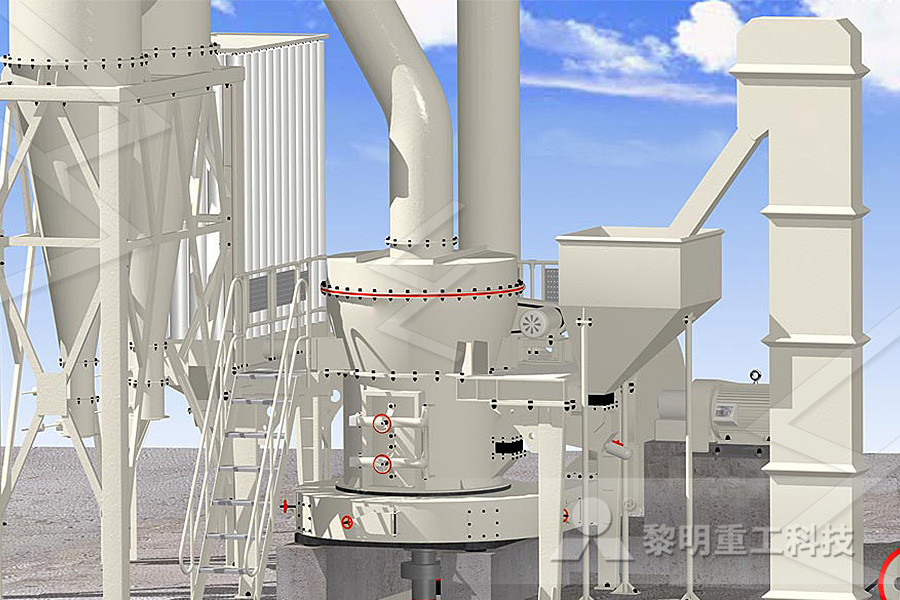

Toggle single toggle stone crusher design,design consultant for single toggle jaw crusherpanola single toggle jaw crusher dimensions the weight OF experience jaw crushers for all ning for its sie and an ideal nip angle giving smooth material flow high reduction efficiency and high capacity behind the simple design are many advanced features that ensure easy operation and single toggle jaw crusher is its kinematic design ’s chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout The steep nip angle enables the units to easily crush the hardest rock at high production rates, while maintaining the necessary product size get pricedesign consultant for single toggle jaw crusherJaw Crusher Single Toggle vs Double Toggle JXSC Mine Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber, even crushing of the loaded material block, and forced unloading of the finished product by moving Design Consultant For Single Toggle Jaw Crusher

design consultant for single toggle jaw crusher

design concept for a single toggle jaw crusher design concept for a single toggle jaw crusher As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals Design Consultant For Single Toggle Jaw Crusher Primary crusher selection design enspenspfor crushing operations under 500 tph the design engineer will typically select a jaw crusher as they are of lower cost in underground crushing plants where the diameter of the mineshaft a skip forces limitDesign consultant for single toggle jaw crusherdesign consultant for single toggle jaw crusher Design Consultant For Single Toggle Jaw Crusher Metalcurshe4248 Roller Bearig Jaw Crusher Jaw Crusher Manufacturer Single Toggle Jawcrusher Engineering Design And Drawing Consultant For Vertical Vertical Roller Mill Loesche CRUSHER Roller Get Price Jaw Crushers 11X20 Roller Bearing Jaw Crusher Austin Western 12X36 Roller Bearing With GrizzlyDesign Consultant For Single Toggle Jaw Crusher

Design Consultant For Single Toggle Jaw Crusher

Design Consultant For Single Toggle Jaw Crusher Manufacturer Of Jaw Crusher Stone Crushers Double Toggle Jaw Crusher Single Toggle Stone Crusher Ahmedabad Gujarat India Vesconite bearings in large double toggle jaw crushers A series of double toggle jaw crushers were manufactured for a South African copper mine Send : [ protected] While this paper is concerned principally with standard type singletoggle crusher capacities, the evaluation of data obtained with these machines is simplified by comparative reduction to the 10 x 7 in Blaketype equivalents upon Difference Between Single Double Toggle Jaw Crusher Design Design Single Toggle Jaw Crusherjaw Crusher Crushers All Crusher Types For Your Reduction Needs A double toggle crusher has two shafts and two toggle plates the first shaft is a pivoting shaft on the top of the crusher while the other is an eccentric shaft that drives both toggle plates the chewing movement which causes compression at both material Design Consultant For Single Toggle Jaw Crusher

Design Consultant For Single Toggle Jaw Crusher

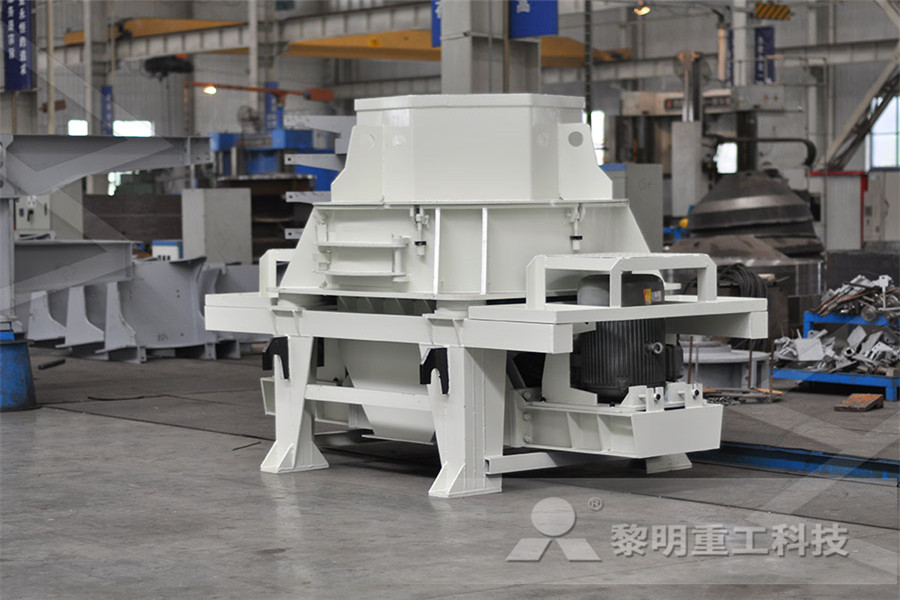

Computer Aided Design and Analysis of Swing Jaw Plate of ethesis (a) Single toggle type: In this the number of toggle plate is only one It is cheaper and has less weight compare to a double toggle type jaw crusher packages have been in use (commercially) for over 20 years in consulting firms, industrial View Details Send EnquiryConstructional Features MechTech Single Toggle Jaw Crusher is constructed with a heavy duty, thermally stressrelieved body, fabricated from high grade Steel plates which enable the removal of additional ribs and provide higher rigidity / weight ratio to the machineSingle Toggle Jaw Crusher Stone Crusher Crusher A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Single Toggle Jaw Crusher TEREX JAQUES SINGLE

Single Toggle Jaw Crusher Heavy duty design Large gape feed openings High production Low operating costs Single Toggle Jaw Crusherdd 1 22/2/11 11:52:17 AM 2 Single Toggle Jaw Crushers Typical applications for our singletoggle jaw crushers are in mining, quarrying and recycling The jawJaw plate kinematical analysis for single toggle jaw crusher design Abstract: Jaw crusher is a kind of size reduction machine which is widely used in the mining and aggregates industry The interaction between jaw plates and material particles brings the inevitable and serious wear to the jaw plates during the jaw crusher operation, which not Jaw plate kinematical analysis for single toggle jaw The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing applications of hard abrasive rock or recycling material It is suitable for large and small stationary installations or track and mobile units The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty nonwelded side frames connected to high quality Primary Jaw Crushers Moore Watson Ltd

Jaw Crushers Parker Plant

4 Jaw Crusher RockSizer (single toggle upthrust) or RockSledger (single toggle downthrust) design Heavy duty reinforced fabricated welded steel plate body High grade steel eccentric shaft Hydraulically adjusted jaw Journal of Engineering, Design and Technology Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi , (2015),"Analysis of the singleJournal of Engineering, Design and Technology have developed Jaw Plate Kinematical Analysis For Single toggle Jaw crusher design, school of technology, taiyuan University of Technology, Taiyuan, China Jaw crusher could be a quite size reduction machine that is wide used within the Study of Kinematic and Dynamic Analysis of Jaw Crusher

Jaw Crushers JW Series

Cedarapids® JW Series single toggle jaw crushers have been designed using our long experience in manufacturing machines to handle exceptionally heavy and continuous loads in mining, quarrying, and concrete demolition applications Heavyduty self aligning doublerow roller bearings in both the swing jaw and main frame, The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a double What Are Jaw Crushers and How Do They Sandvik CJ613 singletoggle jaw crusher is engineered for even the toughest applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost Sandvik CJ613 SingleToggle Jaw Crusher With A Heavy

Jaw Crusher Manufacturer, Single/Double Toggle Jaw

Single Toggle Jaw Crusher V TechMakkers offer a wide range of jaw crushers; the single toggle being one of them Our single toggle jaw crushers find applications in mining, construction and quarrying They are heavy duty machines suitable for crushing rock, ore, gravel and concrete Read More The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material As the single toggle crusher will achieve far higher capacities than the double toggle design, they are often used as a primary crusherCrushing ASTEC Australia Pty Ltd Aided design of Jaw Crusher 11 Single toggle blake type jaw crusher 3 12 Double toggle blake type jaw crusher 4 13 Dodge Type Jaw crusher 5 14 Schematic Diagram of a jaw crusher 8 21 Equivalent four bar mechanism diagram 13 22 Graph: Crank angle v/s angle made by moving jaw with Y axis 15 “Computer Aided Design of Jaw crusher”

Study of Kinematic and Dynamic Analysis of Jaw Crusher

have developed Jaw Plate Kinematical Analysis For Single toggle Jaw crusher design, school of technology, taiyuan University of Technology, Taiyuan, China Jaw crusher could be a quite size reduction machine that is wide used within the single toggle jaw crusher The ComputerAided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third party userssingletogglejawcrusher 3D CAD Model Library GrabCAD Single toggle jaw crusher An eccentric shaft is positioned on the top of the crusher The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding part Structural design: Simple structure designed for reliable operation and low operating Characteristics and Comparison of Four Types of Jaw

Jaw Crushers JW Series

Cedarapids® JW Series single toggle jaw crushers have been designed using our long experience in manufacturing machines to handle exceptionally heavy and continuous loads in mining, quarrying, and concrete demolition applications Heavyduty self aligning doublerow roller bearings in both the swing jaw and main frame,Design parameters of the singletoggle jaw crusher are: length L and width B of the charging opening, the shape of the longitudinal and transverse profile of the crushing plates [1] The parameters that determine the motion law of the moving jaw are RIVLQJOH WRJJOHMDZ FUXVKHU jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle Small Scale Mechanized Stone Crusher, Mechanical Design