limestone calcination process r

2021-12-30T00:12:59+00:00

Calcination of Limestone IspatGuru

02/05/2013 Calcination of Limestone Calcination or calcining is a thermal treatment process to bring about a thermal decomposition The process takes place below the melting point of the product The name calcination is derived from the Latin An excavator loads the loosened limestone into dump trucks for delivery to the onsite crushing plant This continuousfeed process crushes limestone chip into a range of sizes Limestone chip 15–50 mm in size is sent to the calcination plant, while other sizes are used in other processes Acknowledgement: McDonald’s Lime Limited Step 3 Arrival at calcination plantCalcination Science Learning HubThe term “calcinations of limestone” refers to the process of thermal decomposition into quick lime and carbon dioxide It is frequently referred to as “calcinations” Decomposition of limestone is characterized by very simple chemical reactions Complexity is seen to arise when dealing with dolomite, which is believed to cause a change in crystallography and Lime Calcination SpringerLink

Calcination an overview ScienceDirect Topics

Calcination of limestone takes places essentially at about 1000 °C The reaction is highly endothermic and consumes large amount of thermal energy (1126) that comes from the burning of coke Furthermore, limestone decomposition releases CO 2 gas, and the CO 2 gas will react further with coke through Boudouard reaction (1127) , leading to extra solution loss of carbonIn limestone calcination, a decomposition process that occurs at 900 to 1050 °C, the chemical reaction is CaCO 3 (s) → CaO (s) + CO 2 (g) Today, this reaction largely occurs in a cement kiln The standard Gibbs free energy of reaction in [J/mol] is approximated as Δ G ° r ≈ 177,100 J/mol − 158 J/ (mol*K) * TCalcination WikipediaCalcination reactions usually take place at or above the thermal decomposition temperature (for decomposition and volatilization reactions) or the transition temperature (for phase transitions) This temperature is usually defined as the temperature at which the standard Gibbs free energy for a particular calcination reaction is equal to zero In limestone calcination, a decomposition process that occurs at 900 to 1050 °C, the chemical rWhat are the influencing factors of calcination of limestone?

FLASH CALCINATION OF LIMESTONE IN A BENCHSCALE

decomposition of limestone was obtained by nonisothermal thermogravimetric analysis method Calcination data obtained at 2, 5, and 10 K/min linear heating rates in N2and in 10, 20, and 50 kPa CO2were analyzed by several kinetic analysis methods to determine the reaction order,Calcination is a common process, the most recognized example of which is the dissociation of calcium carbonate to create calcium oxide and carbon dioxide in the production of cement from limestone Other applications of calcination include: Catalyst preparation Diatomaceous Earth processing Kaolin Clay processing Conversion of Spodumene to LithiumWhat is Calcination? FEECO International Inc18/02/2022 During the calcination process, limestone enters from the top of the kiln, moves in the direction of gravity inside chamber, and passes through the preheating zone, the calcination zone and the cooling zone in turn, so that calcium carbonate is heated and decomposed, and finally pushed out from the hydraulic cylinder of the discharge platformProcesses Free FullText Study on GasSolid Heat

What are the influencing factors of calcination of

Calcination of limestone is a process of reaction between a series of physical and chemical changes According to these changes, calcination of limestone in kiln can be divided into three sections: The series of physical and chemical A process option to remove these pollutants from the flue gas is by injection of sorbents downstream of a boiler and upstream of a particulate control device Activated carbon (AC) is a suitable sorbent to capture vaporphase mercury and calciumbased sorbents such as quicklime (CaO) and hydrated lime (Ca(OH)2) are suitable sorbents to capture SOx and HCl This FLASH CALCINATION OF LIMESTONE IN A BENCHSCALE The invention features methods and systems for producing commercial quality carbon dioxide (CO2) of 90% to +99% purity using, wet, fine particle limestone produced in a manufacturing operation, for instance, a limestone quarry as a feedstock to a multi stage limestone calcination process This process may be fueled with negative cost waste water treatment plant (WWTP) WOA1 Process and system for calcining fine

Challenges in Limestone Processing

Calcination of Limestone Limestone Processing Issue: Emission Control Rotary kilns are most often used to produce lime products in the United States Hot combustion gases and limestone move counter currently within the 18/02/2022 During the calcination process, limestone enters from the top of the kiln, moves in the direction of gravity inside chamber, and passes through the preheating zone, the calcination zone and the cooling zone in turn, so that calcium carbonate is heated and decomposed, and finally pushed out from the hydraulic cylinder of the discharge platform The combustion fuel Processes Free FullText Study on GasSolid Heat 11171 Process Description 15 Lime is the hightemperature product of the calcination of limestone Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains 30 to 45 percent magnesium 1117 Lime Manufacturing United States Environmental

Limestone processing

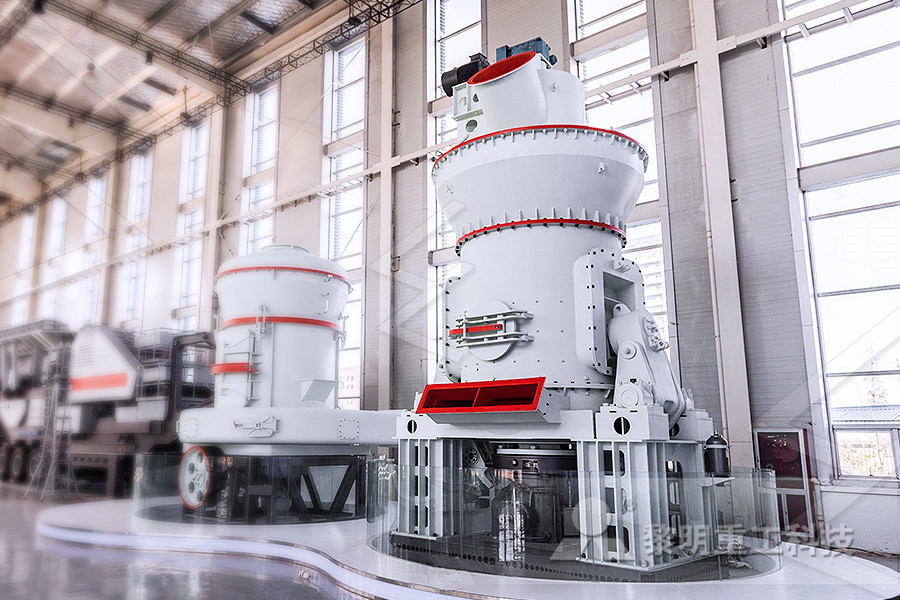

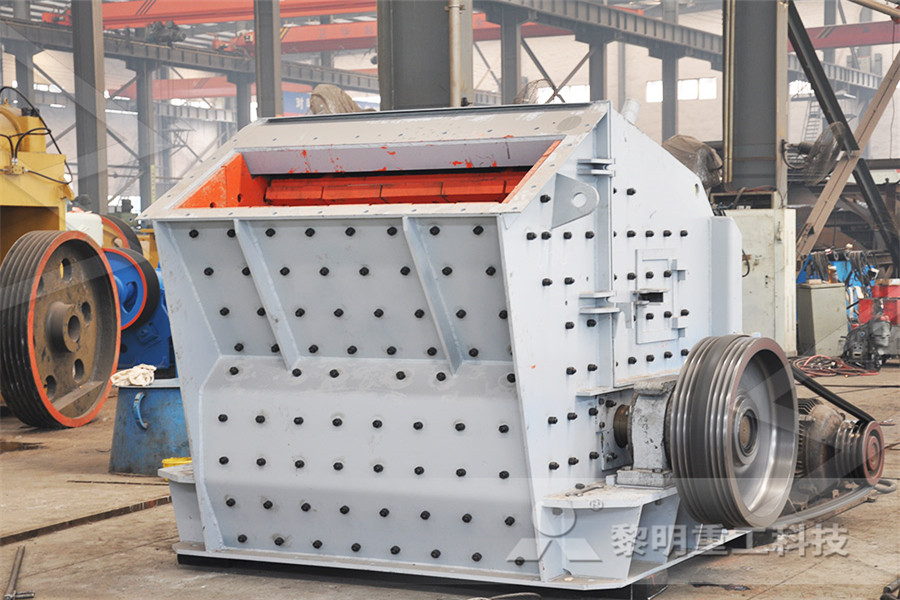

21/03/2022 The main component of limestone is calcium carbonate (CaCO3), which can be directly crushed into crushed stone aggregates for the production of building materials, or fired into quicklime through specific equipment Go! Kangqiao Industrial Area,Pudong,Shanghai (+86) 021 [ protected] English ; Get a quote Home ; About us; Solution Gold As far as the industrial calcination process is concerned, there is still a need for an experimental survey on Arrhenius law parameters, as apparent frequency factor and activation energy, referring to Brazilian limestones The knowledge of these thermokinetic parameters may contribute to energy saving during the industrial calcination process, as well as for allowing the use of Calcination thermokinetics of three Brazilian limestones 01/04/2001 Calcination of limestone The evaluation of the dissociation completion was performed by measuring the mass loss of the samples before and after calcination The mass loss corresponds to the released amount of CO 2 during the calcination process The results are considered satisfactory and in accordance with the data obtained by TG and The effects of limestone characteristics and calcination

Simultaneous Calcination Sulfation of Limestone in CFB

together with limestone calcination as long as SO2 was present In the weightgrowth stage, the sulfation ratio at 60 min in simultaneous calcination/sulfation is 307% higher than that in the sequential calcination then sulfation process The weight loss rate of limestone calcined in theThis continuousfeed process crushes limestone chip into a range of sizes Limestone chip 15–50 mm in size is sent to the calcination plant, while other sizes are used in other processes Acknowledgement: McDonald’s Lime Calcination Science Learning HubFigure 1: The Calix Flash Calcination process Of RD interest are the LEILAC 1 (Low Emission Intensity Lime and Cement) and LEILAC2 Projects LEILAC was a Horizon 2020 consortium project that ran from 2016 until June 2021 It involved the development of Calix’s technology to withstand the higher temperatures required to calcine limestone rather than the Decarbonising lime: Calix’s calcination technology

The calcination of limestone — Studies on the past, the

The calcination of limestone is one of the oldest technical processes and it is still of actual interest Very early calcitic mortars from Turkey have been investigated and compared with materials of other early civilisations ie with Egyptian mortars containing gypsum as well as medieval dolomitebased mortars from alpine regions29/09/2014 calcination time is negligible at 950 and 1000 ° C However, 900 ° C is the most common calcination temperature for Calooping technology, therefore when the e ff ect of CaO sintering on the (PDF) Sintering of Limestone in Calcination of Limestone Limestone Processing Issue: Emission Control Rotary kilns are most often used to produce lime products in the United States Hot combustion gases and limestone move counter currently within the Challenges in Limestone Processing

Simultaneous Calcination Sulfation of Limestone in CFB

together with limestone calcination as long as SO2 was present In the weightgrowth stage, the sulfation ratio at 60 min in simultaneous calcination/sulfation is 307% higher than that in the sequential calcination then sulfation process The weight loss rate of limestone calcined in the21/03/2022 The main component of limestone is calcium carbonate (CaCO3), which can be directly crushed into crushed stone aggregates for the production of building materials, or fired into quicklime through specific equipment Go! Kangqiao Industrial Area,Pudong,Shanghai (+86) 021 [ protected] English ; Get a quote Home ; About us; Solution Gold Limestone processing18/02/2022 During the calcination process, limestone enters from the top of the kiln, moves in the direction of gravity inside chamber, and passes through the preheating zone, the calcination zone and the cooling zone in turn, so that calcium carbonate is heated and decomposed, and finally pushed out from the hydraulic cylinder of the discharge platform The combustion fuel Processes Free FullText Study on GasSolid Heat