process of making steel from iron ore r

2022-03-20T15:03:06+00:00

Process of Steelmaking from Iron Ore Huaruo (Shanghai

Its production process is basically similar, melting pig iron into hot metal and then adding some substances in the hot metal, such as oxygen, and iron ore, which makes it react with the carbon in the hot metal so as to reduce the carbon content in the hot metal Then pour the purified hot metal into the mold and make it into steel after cooling01/11/2017 Once the pig iron ore has been produced it is sent to an basic oxygen furnace, or BOF, to turn it into steel Molten iron from a blast furnace is “charged” (poured from a This is how iron ore is turned into steelProcess Of Making Steel From Iron Ore To make steel, iron ore is first mined from the ground It is then smelted in blast furnaces where the impurities are removed and carbon is added In fact, a very simple definition of steel is iron alloyed with carbon, usually less than 1 The following text is taken from the Structural Manual For Process Of Making Steel From Iron Ore

process of making steel from iron ore

03/12/2020 A Look at the Process of Pelletizing Iron Ore for Steel Preparing Iron Ore For PelletizingThe Pelletizing ProcessThe Process Development Behind Iron Ore PelletizingConclusion Iron ore must go through a lengthy preprocessing stage before it can be pelletized a series of steps that work to beneficiate and concentrate lowgrade ores This steel manufacture Modern iron making Iron is manufactured in a blast furnace First, iron ore is mixed with coke and heated to form an ironrich clinker called ‘sinter’ Sintering is an important part of the overall process as it reduces waste and provides an efficient raw material for iron making Coke is produced from carefully selected the process of making steel from iron ore01/11/2017 If you’ve ever wondered how iron ore is turned into steel, look no further This handy infographic from Bank of America Merrill Lynch (BAML) has the answer, be it using a blast or electric arc This is how iron ore is turned into steel

The Steel Manufacturing Process How is Steel Made?

10/04/2020 In this guide to the steel manufacturing process, we’ll explore the history of steel and compare it to how steel is made and used in modern applications History of Steel Production Steel is a discovery of the Iron Age, a period that started around 1200 BCE Iron ore was first mined in Central Asia and Europe, and humans at this time used Iron ore, as mined, is a combination of iron with oxygen and various other unwanted substances, generally known as "gangue" The first metallurgical step is to reduce iron ore to metallic iron, a process which is mostly carried out in a blast furnace, using coke as both a fuel and reducing agent The metallic iron produced by such a furnace The Making of Iron Steel The Iron Ore, Coke and Limes Presentation will help to provide basic principle and brief overview of iron making to steel making process which is cover each and every stage of iron and steel (PDF) ironsteel making From start to finish

How United States Steel changes iron ore into steel

22/06/2018 This video from United States Steel shows all the steps needed to produce steel, from the mine to the final coils of steel sheet To make steel, Iron ore and other iron bearing materials, coke, and limestone are charged into the blast furnace from the top and work their way down, becoming hotter as they sink in the body of the furnace At the bottom of the furnace, 14/03/2018 Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine The Six Main Steps of Iron Ore Processing Multotec Making steel Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic oxygen furnace route, and the electric arc furnace route Both processes are being continually improved Making steel ArcelorMittal

Creating Steel HowStuffWorks

The pig iron, limestone and iron ore go into an openhearth furnace It is heated to about 1,600 degrees F (871 degrees C) The limestone and ore form a slag that floats on the surface Impurities, including carbon, are oxidized and float Step 1 – The iron making process As iron is the main component of steel it firstly needs to be made Iron ore, lime, and coke are placed into a blast furnace and melted The resulting liquid known as molten iron is then formed As The 6 Steps To Modern Steel Production Explained Steel making process – ArcelorMittal Steel is produced from iron ore or scrap Iron ore is a mineral aggregate that can be converted economically into iron The quality of the iron ore is mainly determined by its composition; a high iron content and low sulphur and phosphorus contents are favorable Iron ore can be found all over the world, but its iron Read More ; production process of steel from iron ore

process of making steel from iron ore

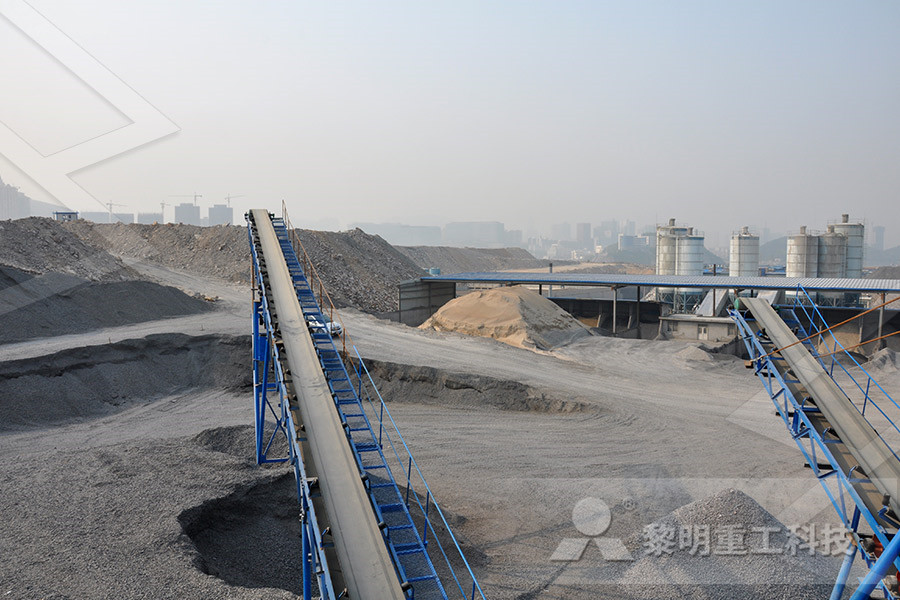

03/12/2020 A Look at the Process of Pelletizing Iron Ore for Steel Preparing Iron Ore For PelletizingThe Pelletizing ProcessThe Process Development Behind Iron Ore PelletizingConclusion Iron ore must go through a lengthy preprocessing stage before it can be pelletized a series of steps that work to beneficiate and concentrate lowgrade ores This How to make steel from iron ore: The raw materials of blast furnace ironmaking are iron ore and coke, but there will be a further processing flow before iron ore and coke enter the blast furnace, namely iron ore sintering and coking coal After the raw materials are solved, they will be put into the blast furnace, and these raw materials will How to Make Steel from Iron Ore and Its Future Prospect Steel making process – ArcelorMittal Steel is produced from iron ore or scrap Iron ore is a mineral aggregate that can be converted economically into iron The quality of the iron ore is mainly determined by its composition; a high iron content and low sulphur and phosphorus contents are favorable Iron ore can be found all over the world, but its iron Read More ; production process of steel from iron ore

The 6 Steps To Modern Steel Production Explained Metro Steel

Step 1 – The iron making process As iron is the main component of steel it firstly needs to be made Iron ore, lime, and coke are placed into a blast furnace and melted The resulting liquid known as molten iron is then formed As molten iron still contains around 4% – 45% impurities such as carbon which in turn make the metal brittle, they need to be eradicated Step 2 does 03/07/2020 Steel Manufacturing Process Iron Making iron is the first step in the production of steel Iron is usually made from iron ore, coal and limestone – although some plants around the world have developed alternative methods of iron manufacture These newer methods require slightly different raw materials but iron ore, coal and limestone remain the starting point for Manufacturing Process Of Steel Properties Fabrication 21/06/2018 The plants for the production of pig iron or steel are called ironworks An ironworks (or iron works) is an industrial plant for the production of steel from iron ores! Before the iron ores can be fed to the ironworks, they must first be mined (ore extraction) and specially processed for the blast furnace process (ore processing) These process steps are Iron ore mining and dressing tecscience

The Manufacture of Steel NZ Institute of Chemistry

Zealand are both unusual, making the overall process almost unique New Zealand is also one of the few countries that has increased steel production over the last decade Its current share of the domestic steel market is about 90% THE MANUFACTURING PROCESS Iron ore is converted to steel via two main steps The first involves the production of molten iron and the Courtesy of iron ore, steel is all around us The production of steel from iron ore has increasingly been employing the pelletizing or balling technique as a result of the many benefits it can offer, combined with changes in the market that have made pellets more favorable Below is a look at this critical processIron Ore Pelletization FEECO International IncMM3020: Iron making and steelmaking (201213II) Instructor In charge: Dr Ajay Kumar Shukla Department of Metallurgical and Materials Engineering IIT Madras, India Learning Objectives To apply the principles of physical chemistry and transport phenomena (heat, mass and momentum) to the process steps in Iron and Steelmaking as practiced in integrated steel plants Be able Ironmaking and steelmaking Indian Institute of

The Six Main Steps of Iron Ore Processing Multotec Canada

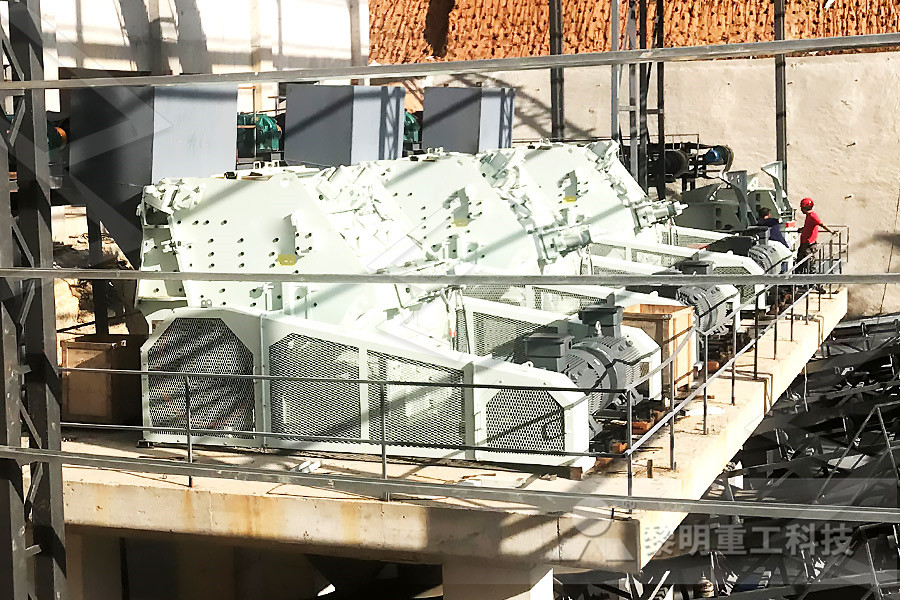

14/03/2018 Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiency Fine particles make the crusher less